How to Make Your Own Stickers Using Cricut invites you into the creative world of sticker-making, where the possibilities are as limitless as your imagination. With a Cricut machine at your disposal, you can craft personalized stickers that reflect your unique style, making them perfect for various projects such as scrapbooking, decorating, or even as thoughtful gifts. This guide will walk you through the entire process, from setting up your Cricut to cutting and finishing your custom designs, ensuring that you are well-equipped to embark on this exciting endeavor.

Introduction to Cricut Stickers

Creating your own stickers with a Cricut machine is both a rewarding and creative endeavor. It allows individuals to personalize their projects with unique designs that reflect their style and preferences. With a Cricut, the possibilities are virtually endless, enabling the production of high-quality stickers that can be used for various applications, from home decor to personal stationery.The benefits of making your own stickers using a Cricut include cost efficiency, customization, and versatility.

Instead of purchasing pre-made stickers, crafting them at home provides the opportunity to design stickers that meet specific needs and tastes. With a Cricut machine, users can create stickers in various shapes, sizes, and finishes, such as matte, glossy, or clear.

Types of Stickers Created with Cricut

Cricut machines facilitate the creation of a wide range of sticker types suited for different purposes. Some common types include:

- Die-Cut Stickers: These are cut to the exact shape of the design, allowing for intricate and detailed graphics, perfect for branding or decorative uses.

- Vinyl Stickers: Made from durable vinyl, these stickers are ideal for outdoor use, as they are weather-resistant and long-lasting.

- Printable Stickers: These stickers can be printed on compatible sticker paper and then cut using the Cricut, offering vibrant colors and intricate designs.

- Transfer Stickers: Often used for decals, these are designed to be applied smoothly on surfaces, making them ideal for car windows or wall art.

Materials Required for Sticker Making

When making stickers with a Cricut machine, certain materials are essential for achieving the best results. The following list Artikels the necessary items to get started:

- Cricut Machine: The primary tool required to cut and create designs.

- Cutting Mat: A sticky surface on which the material is placed for accurate cutting.

- Sticker Paper: Special paper designed for printing and cutting stickers, available in various finishes.

- Vinyl Sheets: Used for creating durable stickers, especially outdoor decals.

- Design Software: Software such as Cricut Design Space is essential for designing custom stickers.

“The ability to create personalized stickers opens a world of expression and creativity.”

With these materials at hand, your journey into the world of Cricut sticker making is set for a smooth and enjoyable experience. The combination of creativity and technology allows for endless possibilities.

Setting Up Your Cricut Machine

Setting up your Cricut machine is an essential first step in creating stunning custom stickers. Proper configuration ensures that your machine operates efficiently and produces high-quality designs. This section will guide you through the necessary steps to get your Cricut ready for sticker making.Connecting your Cricut requires a few straightforward steps. First, ensure that you have all the components, including the Cricut machine, power supply, and USB cord if connecting to a computer.

Follow these steps to complete the setup:

Steps to Set Up Your Cricut Machine

- Unbox your Cricut machine and carefully remove all packaging materials.

- Place the machine on a flat, stable surface that allows for sufficient space for operation.

- Connect the power supply to the machine and plug it into a wall outlet.

- Turn on the machine using the power button.

- For a USB connection, use the USB cord to connect the Cricut to your computer. If you’re using a mobile device, ensure you have the appropriate Bluetooth setup if your machine supports wireless connectivity.

After connecting your machine, it’s essential to install the necessary software to design your stickers. Below are the software options compatible with Cricut that can enhance your sticker-making experience.

Software Options for Designing Stickers

Using the right software can significantly improve your design process. The following software options are compatible with Cricut machines and are popular among crafters:

- Cricut Design Space: This is the official software provided by Cricut, offering a user-friendly interface for creating, editing, and cutting designs directly from your computer or mobile device.

- Adobe Illustrator: A professional design tool that allows for advanced graphic design capabilities, perfect for creating intricate and customized sticker designs.

- Inkscape: A free vector graphic editor that is an excellent alternative for users looking to create complex designs without the cost associated with premium software.

- Silhouette Studio: While primarily used for Silhouette machines, this software is also compatible with Cricut and offers powerful design features.

Furthermore, connecting your Cricut machine to a computer or mobile device is crucial for utilizing these software options effectively. Follow these guidelines for a seamless connection:

Connecting Your Cricut to a Computer or Mobile Device

To connect your Cricut machine to a computer or mobile device, follow these steps based on your connection type:

USB Connection to Computer

1. Ensure the Cricut machine is powered on and connected via the USB cable to your computer. 2. Open Cricut Design Space on your computer. 3.

The software should automatically detect your machine; follow the on-screen instructions to complete the connection.

Bluetooth Connection to Mobile Device

1. Ensure Bluetooth is enabled on your mobile device. 2. Power on your Cricut machine and navigate to the Bluetooth settings. 3.

Select your Cricut machine from the list of available devices. 4. Open the Cricut Design Space app and follow the prompts to initiate the connection.By following these steps, you will ensure that your Cricut machine is set up correctly and ready to create beautiful stickers. A well-prepared machine will lead to more enjoyable and productive crafting sessions.

Designing Your Sticker

Creating your own stickers begins with the thoughtful design process. This step is crucial as it allows for personalization and creativity, enabling you to produce unique stickers that resonate with your style or brand. Utilizing design software effectively will ensure that your artwork translates well into actual stickers, capturing the attention of your intended audience.To create custom sticker designs, you can use various design software options such as Adobe Illustrator, Canva, or the Cricut Design Space itself.

Each of these platforms offers unique tools and functionalities that can help bring your ideas to life. When using these programs, ensure you are familiar with the basic functionalities, such as layers, shapes, and color palettes. This knowledge will aid you in crafting intricate designs and allow for experimentation with different styles.

Design Elements to Consider When Making Stickers

When designing stickers, it’s important to consider various design elements that contribute to the overall appeal and effectiveness of your stickers. These elements can enhance the visual impact and ensure the final product meets your expectations. Below are essential design aspects to contemplate:

- Shapes: The shapes of your stickers can significantly influence their visual impact. Consider using geometric shapes for a modern look or organic shapes for a more whimsical feel.

- Colors: Color choice is vital in conveying emotions and attracting attention. Opt for a color palette that complements your theme and ensures high visibility.

- Fonts: Select fonts that are legible and reflect the tone of your design. Play with sizes and placements to create hierarchy and emphasis.

- Graphics: Incorporate relevant graphics or illustrations that enhance your message. Original artwork can give your stickers a unique flair.

- Size: Consider the size of your stickers in relation to their intended use. Smaller stickers might work well for labeling, while larger designs may be suitable for decorative purposes.

Preparing Images for Optimal Sticker Quality

For the best sticker quality, it is essential to prepare your images properly before printing. The resolution and format of your images can significantly affect the final outcome. Here are key tips for image preparation:

High-resolution images (300 DPI) ensure clarity and sharpness when printed, while low-resolution images may appear pixelated.

When working with images, follow these guidelines:

- Image Format: Use formats such as PNG or SVG, which support transparency and scalability. This allows for cleaner edges and better integration with your designs.

- Resolution: Ensure that your images are at least 300 DPI. This is particularly important for printing, as higher resolution images result in better quality stickers.

- Color Mode: Utilize CMYK color mode for printed designs to ensure that the colors appear as intended. RGB is suitable for digital displays but can differ when printed.

- Background Removal: If your design includes a subject with a background, remove it to create a cleaner, professional look. This helps the sticker blend into its intended surface.

- Test Prints: Before finalizing, conduct test prints of your designs to ensure that colors and sizes meet your expectations. This step can save time and materials in the long run.

Choosing the Right Materials

Selecting the appropriate materials is a crucial step when crafting your own stickers using a Cricut machine. The choices you make can significantly impact the durability, appearance, and functionality of your stickers. Understanding the various types of sticker paper and adhesive options available will help you make informed decisions tailored to your project’s specific needs.

Types of Sticker Paper

When it comes to sticker paper, there are several options available that cater to different preferences and applications. Below is a summary of the most common types:

- Matte Sticker Paper: Provides a non-glossy finish, making it ideal for writing on. It is suitable for indoor use and offers a professional appearance.

- Glossy Sticker Paper: Features a shiny surface that enhances colors and provides a vibrant finish. It is perfect for high-quality, eye-catching designs, especially for outdoor use.

- Transparent Sticker Paper: Offers a see-through effect, allowing for unique layering on various surfaces. This type is great for window decals or labels.

- Vinyl Sticker Sheets: Known for their durability and weather resistance, vinyl stickers can be used for both indoor and outdoor applications. They are available in various finishes, including matte and glossy.

Comparison of Vinyl and Paper Stickers

Understanding the differences between vinyl and paper stickers will aid in selecting the right type for your project. Each material has its advantages and disadvantages.

- Vinyl Stickers:

- Pros: Highly durable, waterproof, and resistant to tearing. Ideal for outdoor use and can withstand varying weather conditions.

- Cons: Generally more expensive than paper options and may require special cutting settings on the Cricut.

- Paper Stickers:

- Pros: Cost-effective, easy to print, and available in a wide range of textures and finishes. Suitable for temporary use and indoor applications.

- Cons: Less durable than vinyl, prone to damage from moisture, and may fade over time when exposed to sunlight.

Selecting Adhesive Strength

The adhesive strength of your stickers is essential to consider, particularly in relation to their intended use. The adhesive can determine how well your stickers adhere to surfaces and their longevity.

- Permanent Adhesive: Provides a strong bond and is suitable for stickers that are intended for long-term use, such as car decals or outdoor signage. It is resistant to moisture and heat.

- Removable Adhesive: Allows for easy application and removal without leaving residue behind. Ideal for temporary stickers, such as decorations or promotional materials.

- Repositionable Adhesive: Offers flexibility, allowing users to adjust the placement of stickers multiple times without compromising adhesion. Best for wall decals and repositionable labels.

“Choosing the right materials and adhesives ensures that your stickers are not only visually appealing but also suited for their intended purpose.”

Cutting Your Stickers

Cutting your stickers is a crucial step in the sticker-making process, allowing you to transform your designs into tangible items. Utilizing the Cricut cutting machine can streamline this step significantly, ensuring precise cuts and clean edges for professional-looking stickers.Before initiating the cutting process, it’s essential to understand the various adjustments that may be necessary depending on the material being used.

Different materials will require unique settings to achieve optimal results, ensuring that your stickers not only look great but are also durable.

Step-by-Step Cutting Process

The cutting process with a Cricut machine is straightforward, provided that you follow these essential steps:

1. Prepare Your Design

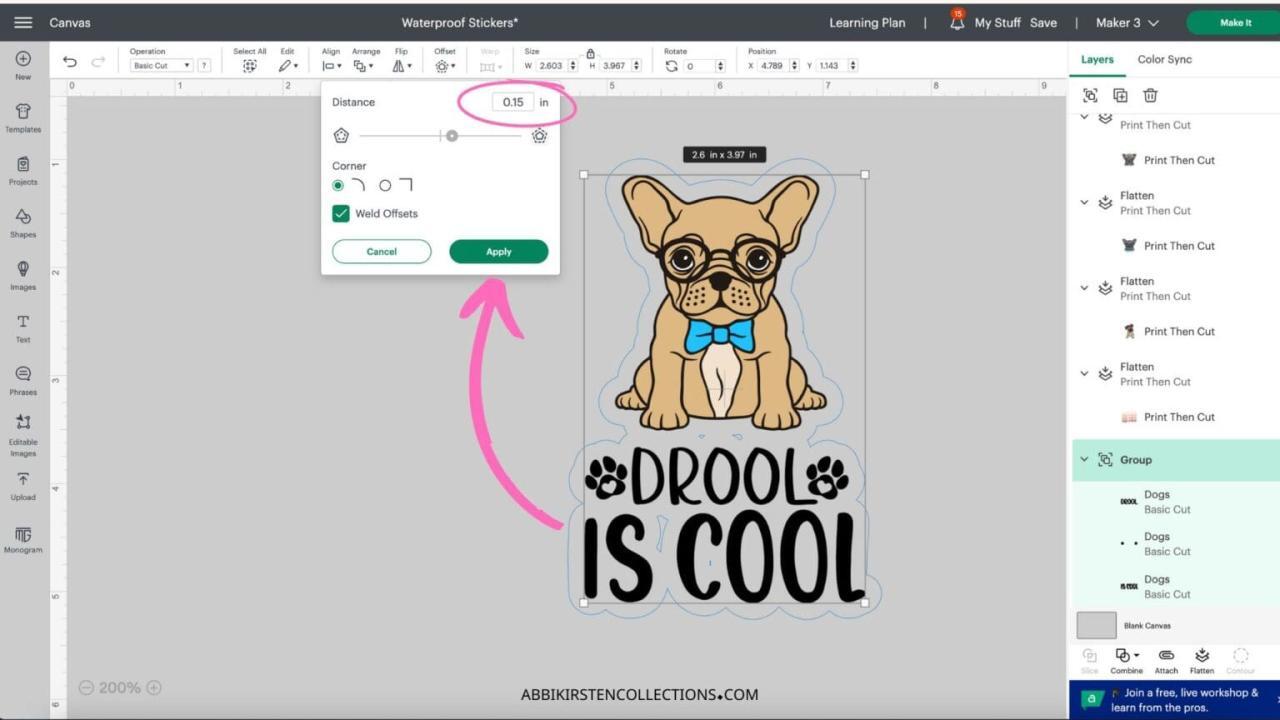

Load your design into the Cricut Design Space and ensure it is correctly sized for the material you will be using.

2. Select Material Type

Choose the material type from the drop-down menu in the Design Space. This selection adjusts the blade depth and cutting pressure automatically.

3. Load the Mat

Place your chosen material onto the cutting mat. Make sure it is securely adhered to avoid any shifting during the cutting process.

4. Insert the Mat into the Machine

Align the mat with the guides on your Cricut machine and press the ‘Load’ button. The machine will pull the mat in automatically.

5. Start the Cutting Process

Press the ‘Go’ button on your machine or in the Design Space. The machine will begin to cut according to your design.

6. Unload the Mat

Once the cutting is complete, press the ‘Unload’ button to release the mat from the machine.

7. Remove the Stickers

Carefully peel the stickers off the mat using a weeding tool to lift the edges without damaging the cuts.

Settings Adjustments for Various Materials

Choosing the right settings is imperative to ensure clean cuts that do not damage the material. Below are recommended settings for common materials used in sticker making:

Paper Stickers

Use the ‘Medium Cardstock’ setting, with a blade depth of 3, and a cutting pressure of 160. This setting ensures clean cuts through the paper without tearing.

Vinyl Stickers

For permanent adhesive vinyl, select the ‘Vinyl’ setting. A blade depth of 2 and medium cutting pressure are advisable, allowing the blade to cut through the vinyl while leaving the backing intact for easy application.

Printable Sticker Paper

Use the ‘Printable Vinyl’ setting with a blade depth of 3 and a pressure setting of 175. This ensures that the print is accurately cut while maintaining the integrity of the sticker paper.

Safety Precautions While Cutting Stickers

Safety should always be a priority when using cutting machines. Below are essential precautions to consider:

Keep Hands Clear

Always keep your hands away from the cutting area while the machine is in operation to prevent injury.

Use a Stable Surface

Ensure the Cricut machine is placed on a stable surface to prevent it from tipping or moving during cutting.

Avoid Overloading the Mat

Do not overload the cutting mat with too much material, as this can cause jams or misalignments during cutting.

Monitor the Machine

Always supervise the cutting process to quickly address any issues that may arise.

Use the Correct Blade

Ensure that the blade you are using is sharp and appropriate for the material to avoid accidents and achieve optimal results.By following these steps and precautions, you can achieve high-quality stickers with your Cricut machine while ensuring a safe crafting environment.

Finishing Touches

After cutting your stickers, the finishing touches are essential to give them a professional look and ensure their longevity. This stage involves weeding out the excess material, applying transfer tape, and sealing your stickers for added durability. Each step contributes to the overall quality and usability of your creations.Weeding is the process of removing the unwanted portions of vinyl or paper after the cutting phase.

This step is crucial as it reveals the final sticker design. Start by gently peeling away the excess material from the edges, using a weeding tool to lift small areas with precision. Be careful not to damage the actual stickers during this process. For intricate designs, take your time to ensure that all stray bits are removed, allowing the adhesive side to be ready for application.

Tools for Applying Finishing Touches

Having the right tools on hand can significantly enhance the finishing process of your stickers. Here is a list of essential tools you will need:

- Weeding Tool: This is a fine pointed tool that helps in removing excess material from your stickers efficiently.

- Transfer Tape: This tape is used to lift your sticker from its backing and transfer it onto the desired surface without losing alignment.

- Scraper Tool: A scraper tool is useful for smoothing out the sticker once it is on its final surface, ensuring there are no air bubbles.

- Scissors: Sharp scissors may be required for trimming the edges of your stickers or transfer tape for a cleaner finish.

- Ruler or Straight Edge: For precise trimming or alignment of your stickers, a ruler or straight edge can help ensure straight lines.

Sealing your stickers enhances their durability and protects them from elements such as water and fading. Various methods can achieve this, depending on the materials used for the stickers. Here are effective sealing methods:

Methods for Sealing Stickers

Applying a protective seal can extend the life of your stickers significantly. Below are common methods for sealing stickers:

- Laminating: Using a laminating machine or self-adhesive laminating sheets can provide a clear, protective layer over your stickers.

- Clear Spray Sealant: A spray sealant can be applied to the surface of your stickers. Ensure you follow the manufacturer’s instructions for the best results.

- Clear Vinyl Covering: A thin layer of clear vinyl can be applied over the sticker to protect it from scratches and moisture.

- Mod Podge: This versatile product can be brushed over stickers to create a waterproof finish. Allow sufficient drying time for the best effect.

“Applying the right finishing touches transforms your DIY stickers from simple crafts to professional-quality pieces.”

Creative Uses for Stickers

Stickers are a versatile and fun medium for personal expression and creativity. Homemade stickers can be utilized in a variety of projects, adding a personalized touch to numerous endeavors. This section explores several creative applications for stickers, helping you understand the many ways to use your custom designs.One of the most popular applications for homemade stickers is in scrapbooking. Stickers can enhance layouts, complement themes, and create focal points on pages.

Additionally, personalized stickers can be used for gift wrapping, adding a unique flair to presents. They can also serve practical purposes, such as labeling items in your home or office, offering a stylish way to organize.

Examples of Projects with Personalized Stickers

Creating personalized stickers opens up a world of project possibilities. Here are some notable examples:

- Customized Planner Stickers: Design stickers for scheduling, reminders, and motivational quotes to bring flair to your planner.

- Sticker Bombing: Use stickers to cover journals, laptops, or phone cases, transforming everyday items into personal art pieces.

- Party Decorations: Create themed stickers for events, such as birthday parties or weddings, which can be used for invitations, favors, and decorations.

- Artistic Cards: Design stickers that can be used on greeting cards, adding a personalized message or artwork to enhance the sentiment.

- Kids’ Crafts: Encourage creativity in children by providing them with stickers for their own artwork, helping them express themselves in fun and imaginative ways.

Each of these projects demonstrates how customizable stickers can elevate your creative endeavors, making them more personal and engaging.

Marketing and Gifting Stickers

Homemade stickers can also be marketed or gifted to others, expanding their reach beyond personal use. When considering how to share your stickers, think about the following strategies:

- Online Marketplaces: Selling stickers on platforms such as Etsy or Redbubble allows you to reach a wider audience interested in unique and custom designs.

- Local Craft Fairs: Participating in craft fairs or local markets can help you connect with customers in your community, showcasing your work in person.

- Gift Sets: Create themed sticker sets as gifts for friends or family. This could include a mix of stickers for planners, scrapbooking, or decorating.

- Social Media Promotion: Use Instagram or Pinterest to display your sticker designs, sharing usage ideas and inspiring others to purchase or gift them.

- Personalized Gifts: Custom stickers can make excellent gifts on their own or as part of a larger package, such as stationery sets or craft supplies.

By employing these strategies, you can effectively market your stickers or thoughtfully share them with others, amplifying their impact and fostering a community around your creative expressions.

Troubleshooting Common Issues

When embarking on the journey of creating stickers with your Cricut machine, it is essential to be aware of potential challenges that may arise during the process. Understanding common issues can help mitigate frustrations and enhance your crafting experience. This section will address prevalent problems and offer practical solutions to ensure a seamless sticker-making process.

Common Cutting Issues

Cutting issues can significantly hinder your sticker-making efforts. These problems may include incomplete cuts, tearing of materials, or the machine failing to cut at all. Addressing these concerns promptly is crucial for maintaining the integrity of your designs and materials.To effectively troubleshoot cutting issues, consider the following solutions:

- Blade Maintenance: Regularly check the condition of your blade. A dull blade can cause incomplete cuts and tearing. Replace your blade if necessary to achieve clean cuts.

- Material Calibration: Ensure that the material settings on your Cricut machine correspond with the type of material being used. Incorrect settings can lead to improper cutting.

- Mat Condition: Inspect your cutting mat for wear and tear. A worn mat may not hold materials securely, causing cuts to be uneven. Replacing your cutting mat can improve performance.

Design Errors

Design errors can compromise the visual appeal of your stickers. Misalignment, incorrect dimensions, or unintended design elements can detract from your intended outcome. Recognizing and rectifying these errors is vital for creating high-quality stickers.To address design errors effectively, implement the following strategies:

- Double-Check Dimensions: Always verify that your design dimensions match the desired size for your stickers before initiating the cutting process.

- Use the Preview Function: Utilize the preview feature in the Cricut design software to identify any misalignments or unintended elements before cutting.

- Save Multiple Versions: Save different versions of your designs to prevent loss of work and allow for comparisons, ensuring that you can revert to previous iterations if needed.

Maintaining Your Cricut Machine

Proper maintenance of your Cricut machine is essential for optimal performance and longevity. Regular upkeep can prevent many issues from arising, allowing for a smoother crafting experience.Consider the following maintenance tips:

- Regular Cleaning: Clean your machine and its components regularly to prevent dust and debris from affecting performance. Use a soft cloth and isopropyl alcohol to clean the exterior and blades.

- Software Updates: Keep the Cricut software updated to ensure access to the latest features and bug fixes that can enhance functionality.

- Check Connections: Periodically inspect all connections, including power and data cables, to ensure they are secure and functioning correctly.

Regular maintenance and troubleshooting can significantly enhance your crafting experience, allowing you to focus on creativity rather than technical difficulties.

End of Discussion

In conclusion, making your own stickers with a Cricut machine not only allows for creative expression but also provides you with the opportunity to produce high-quality, personalized items that can be enjoyed and shared. By following the Artikeld steps, from design to cutting and finishing, you can overcome common challenges and elevate your sticker-making experience. Embrace your creativity, and let your stickers tell your story!