How to Use the Deep-Point Blade for Thicker Materials stands as a pivotal guide for both novice and seasoned users alike, seeking to enhance their cutting capabilities. The unique design of deep-point blades allows for precision and efficiency when working with various thicker materials, making them an essential tool in many crafting and industrial applications.

In this comprehensive overview, we delve into the intricacies of deep-point blades, exploring their intended purpose, suitable materials, and the advantages they offer over conventional cutting tools. By understanding the preparation, techniques, and maintenance required for optimal performance, users will be equipped to tackle a range of projects with confidence and skill.

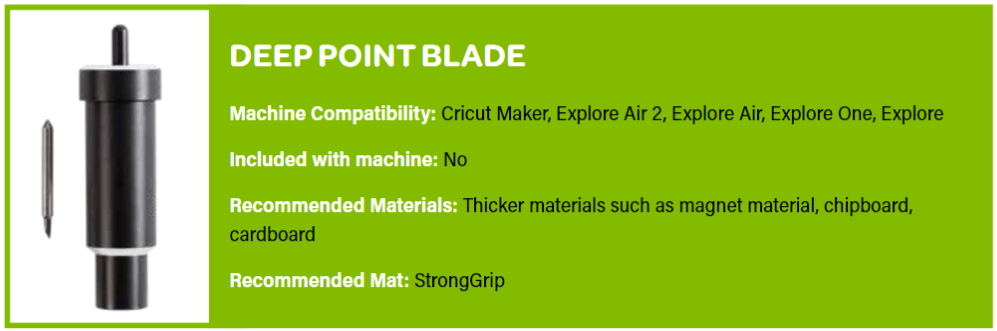

Introduction to Deep-Point Blades

The deep-point blade is a specialized cutting tool engineered for precision and efficiency, particularly suited for thicker materials. With its unique design, this blade extends the cutting depth while maintaining sharpness and stability, making it an essential tool in various crafting and industrial applications. The deep-point blade is designed to create clean, precise cuts, which are pivotal in achieving high-quality results.The design of deep-point blades typically features a pointed tip and a longer cutting edge, which allows for better penetration into thicker materials.

These blades are commonly used with materials such as cardstock, foam, leather, and even some types of acrylic. Their versatility makes them a preferred choice among crafters and professionals alike.

Materials Suitable for Deep-Point Blades

Deep-point blades excel when used with a variety of materials. Understanding the best materials for these blades enhances their effectiveness and showcases their capabilities. The following materials are ideal for deep-point blade applications:

- Cardstock: This paperboard material is widely used in scrapbooking and card-making, where precision cutting is paramount.

- Foam: Ideal for creating shapes and designs in crafts, deep-point blades can easily cut through different densities of foam.

- Leather: The robust design of deep-point blades allows them to cut through thick leather, making them suitable for crafting bags, wallets, and other leather goods.

- Acrylic: Deep-point blades can effectively cut through acrylic sheets, enabling the creation of intricate designs for signage and decorative items.

Advantages of Using Deep-Point Blades for Thicker Materials

The advantages of utilizing deep-point blades for cutting thicker materials are numerous. The following points highlight the key benefits:

- Increased Cutting Depth: The design allows for deeper cuts, which is essential for thicker materials.

- Enhanced Precision: The pointed tip enables more accurate cuts, reducing the risk of material wastage.

- Versatility: These blades can handle a wide range of materials, catering to diverse project requirements.

- Durability: Constructed with high-quality materials, deep-point blades maintain their sharpness longer, providing consistent performance over time.

“The deep-point blade is not just a tool; it’s an investment in achieving precision and quality in your projects.”

Preparing for Use

Before utilizing a deep-point blade for cutting thicker materials, it is essential to ensure that all necessary tools and equipment are in place. Proper preparation not only enhances the efficiency of the cutting process but also significantly contributes to safety and accuracy.The main tools required for using a deep-point blade include a compatible cutting machine, such as a vinyl cutter or a craft machine, a deep-point blade specifically designed for thicker materials, and a stable cutting mat to prevent movement during operation.

Additionally, having spare blades on hand can be beneficial, as thicker materials may wear blades more quickly than standard materials.

Necessary Tools and Equipment

The following tools and equipment are vital for effectively using a deep-point blade on thicker materials:

- Deep-Point Blade: Ensure that the blade is specifically designed for thicker materials to achieve optimal results.

- Cutting Machine: A reliable cutting machine that supports deep-point blades is crucial for maintaining accuracy and efficiency.

- Cutting Mat: A sturdy cutting mat provides a stable surface and protects the underlying work surface from damage.

- Ruler and Cutting Tool: These are necessary for precision measurement and straight cuts if required.

- Protective Gear: Safety glasses and gloves should be worn to protect against any potential debris or sharp blades.

Preparation of thicker materials before cutting is equally important. Ensuring that the material is properly measured, marked, and secured can greatly influence the cutting outcome.

Preparing Thicker Materials

To effectively prepare thicker materials for cutting with a deep-point blade, follow these steps:

- Measuring: Use a ruler to measure the desired dimensions for your cut, ensuring accuracy for the best results.

- Marking: Clearly mark the cutting lines on the material using a pencil or a marker to provide a clear guide during cutting.

- Securing the Material: Firmly place the material on the cutting mat and use tape if necessary to prevent movement.

- Testing the Blade Depth: Before beginning the final cut, perform a test cut on a scrap piece to ensure the blade depth is set correctly for the thickness of the material.

Safety is paramount when handling deep-point blades. Implementing appropriate safety measures minimizes the risk of injury and ensures a safe working environment.

Safety Precautions

When using deep-point blades, adhere to the following safety precautions:

- Use Protective Gear: Always wear safety glasses and gloves to protect against potential injuries from sharp blades and debris.

- Keep Work Area Clean: Maintain a tidy workspace to minimize the risk of accidents and ensure ease of access to tools.

- Avoid Distractions: Stay focused on the task at hand and avoid multitasking to ensure precision and safety.

- Handle Blades with Care: Always handle blades by their plastic housing or base, avoiding direct contact with the cutting edge.

- Secure Loose Clothing: Ensure that any loose clothing or accessories are properly secured or removed to prevent them from getting caught in the cutting machine.

Cutting Techniques

Using a deep-point blade for thicker materials requires specific cutting techniques to ensure precision and efficiency. Mastering these techniques can enhance not only the quality of your cuts but also the lifespan of your blade and safety during the cutting process.The cutting technique employed significantly influences the outcome of your project. It is essential to familiarize yourself with the appropriate methods and angles to achieve optimal results.

This section Artikels a step-by-step guide on effectively using a deep-point blade, elaborates on the impact of cutting angles, and highlights common mistakes to avoid.

Step-by-Step Guide for Using a Deep-Point Blade

To properly utilize a deep-point blade for thicker materials, follow this structured approach:

1. Select the Right Blade

Ensure that the deep-point blade is suitable for the thickness of the material you intend to cut. The blade should be sharp and in good condition.

2. Secure the Material

Use clamps or a stable work surface to hold the material securely in place. This prevents movement during cutting, which could lead to inaccuracies or injuries.

3. Adjust the Cutting Depth

Set the blade to a depth that penetrates through the material without excessive force. A depth that allows going through the material in one pass is ideal.

4. Position the Tool

Hold the cutting tool at a consistent angle, typically between 10 to 15 degrees, to facilitate a smooth cut.

5. Begin Cutting

Initiate the cut with a steady motion, applying even pressure. Avoid forcing the blade, as this can lead to jagged edges or blade damage.

6. Follow the Marked Line

Guide the blade along the marked cutting line, maintaining a steady hand to ensure accuracy.

7. Finish and Inspect the Cut

Once the cut is completed, inspect the edges for smoothness. Additional finishing with sandpaper may be necessary for optimal results.

Impact of Cutting Angles

The angle at which the deep-point blade is held during cutting can drastically affect the cutting process and final outcome. Different angles can lead to variations in the quality of the cut and the efficiency of the operation.

Steeper Angles (15-20 degrees)

A steeper angle can increase the likelihood of a cleaner cut but may require more effort and lead to increased wear on the blade.

Shallower Angles (5-10 degrees)

Shallower angles tend to be easier on the blade and can result in a less aggressive cut, which is ideal for more delicate materials.Understanding these nuances helps in selecting the right angle based on the specific material characteristics, thus optimizing cutting efficiency and accuracy.

Common Mistakes and How to Avoid Them

The following Artikels frequent mistakes made during cutting with a deep-point blade and strategies to prevent them:

Inconsistent Pressure

Applying varying levels of pressure can lead to uneven cuts. Always maintain steady pressure throughout the cut.

Incorrect Cutting Depth

Setting the blade too deep can cause binding or damage to the material. Always assess the thickness before adjusting the depth.

Neglecting Safety Gear

Failing to use protective eyewear and gloves can lead to injuries. Always wear appropriate safety equipment.

Poor Work Environment

A cluttered workspace can lead to accidents. Keep the area tidy and organized to ensure a safe cutting process.

Ignoring Material Characteristics

Different materials have unique cutting requirements. It is essential to understand the behavior of the material when cut, including factors like grain direction and density.By adhering to the suggested techniques and avoiding common pitfalls, users can achieve better results and enhance their overall experience while using deep-point blades for thicker materials.

Maintenance and Care

Proper maintenance and care of deep-point blades are essential to ensure their longevity and effectiveness when cutting thicker materials. By following a few straightforward practices, users can maintain the sharpness of their blades, keep them clean, and recognize when it’s time to replace them. Implementing these measures not only enhances performance but also ensures safety during operation.

Maintaining Sharpness

To maintain the sharpness of deep-point blades, it is important to adopt specific practices that prolong their cutting efficacy. Regular maintenance routines help to ensure the blades remain effective over time.

- Store blades in a protective case to prevent accidental impacts or dulling.

- Sharpen blades periodically using a sharpening stone or dedicated blade sharpeners designed for deep-point blades; this should be done following the manufacturer’s recommendations.

- Avoid cutting materials that are too hard or abrasive, which can lead to premature dulling.

Regular attention to these details will preserve blade sharpness and enhance cutting performance.

Cleaning Procedures

After using deep-point blades on thicker materials, it is crucial to implement proper cleaning procedures to maintain the integrity of the blade and prevent build-up that can hinder performance. Cleaning helps to remove debris, resin, or other contaminants that can accumulate during cutting.

- Immediately after use, wipe the blade with a clean, dry cloth to remove any residue or material particles.

- For tougher residues, use a soft brush or a mild solvent to clean the blade, ensuring that you do not damage the cutting edge.

- After cleaning, dry the blade thoroughly to prevent rust or corrosion, especially if the blade is made from carbon steel.

Implementing these cleaning procedures will help ensure that the blade remains in optimal working condition for future cutting tasks.

Signs for Blade Replacement

Recognizing the signs that indicate a deep-point blade needs to be replaced is essential for maintaining safety and efficiency during use. Using a dull or damaged blade can lead to poor cutting performance and increased risk of accidents.

- Visible nicks, chips, or bends on the blade can significantly affect cutting ability and should prompt immediate replacement.

- If the blade requires excessive pressure to cut through materials, it is a clear sign that it has lost its sharpness and should be changed.

- Frequent overheating during operation indicates that the blade is no longer effective and may need to be replaced to ensure safe cutting.

Awareness of these signs will facilitate timely interventions, thereby promoting efficiency and safety in your cutting tasks.

Applications in Various Industries

Deep-point blades serve a crucial role in numerous industries by enhancing the capability to cut thicker materials with precision and efficiency. Their unique design allows for deeper penetration and cleaner cuts, making them ideal for a variety of applications across different sectors. Understanding the specific uses of deep-point blades can help industries optimize their processes and achieve superior results.The versatility of deep-point blades allows them to be effectively utilized in multiple industries, each with its unique projects and requirements.

Here are several industries where deep-point blades have proven to be indispensable:

Manufacturing and Fabrication

In the manufacturing sector, deep-point blades are essential for cutting materials such as metal sheets and thick plastics. These materials often require precise cutting to ensure a proper fit during assembly. For instance, in sheet metal fabrication, deep-point blades can easily cut through sheets of aluminum or stainless steel, enabling the creation of parts for automotive or aerospace applications. This precision minimizes the need for additional finishing processes, thereby saving time and resources.

Textile Industry

The textile industry also benefits from deep-point blades, particularly in the cutting of thick fabrics and layered materials. When producing upholstered furniture or automotive interiors, deep-point blades can efficiently slice through multiple layers of fabric and padding, ensuring clean edges and reducing fabric fraying. This capability is particularly useful for manufacturers who need to produce large volumes of products quickly and efficiently.

Construction and Carpentry

In construction and carpentry, deep-point blades are utilized for cutting wood and composite materials. For example, during the construction of wooden frameworks or furniture, workers can employ deep-point blades to achieve accurate cuts in thicker wooden beams. The blade’s ability to penetrate deeply into the material ensures that cuts are both clean and precise, reducing the likelihood of errors that could compromise structural integrity.

Signage and Displays

The signage and display industry frequently uses deep-point blades to cut thick vinyl, acrylic, and other materials used in signs and promotional displays. For instance, creating custom signs often requires cutting intricate designs into thick sheets of acrylic. The precision offered by deep-point blades allows designers to produce detailed and aesthetically pleasing signs that meet client specifications while maintaining structural durability.

Material Considerations

The choice of blade type is significantly influenced by the materials being cut. Various materials present distinct challenges that must be accounted for when selecting a deep-point blade. For example:

- Metal: When cutting metals such as steel or aluminum, blades with a high tooth count are preferable to achieve clean edges.

- Wood: For cutting hardwoods, deep-point blades with a fine tooth design are recommended to prevent splintering.

- Plastics: Softer plastics may require blades with larger teeth to avoid melting, while harder plastics need sharper blades for clean cuts.

- Composites: When working with composite materials, the blade must be able to handle varying densities, which may require specialized blade coatings.

Understanding the specific material properties is crucial for selecting the appropriate deep-point blade, ensuring optimal cutting performance and reducing wear and tear on the tool.

Troubleshooting Common Issues

When utilizing deep-point blades for thicker materials, various challenges may arise that can affect the quality of your cuts. Understanding these common issues and their solutions is essential for achieving optimal results. This section aims to Artikel typical cutting problems and offer practical solutions, as well as adjustments to accommodate variations in material thickness.

Common Cutting Problems and Solutions

Several issues can occur during the cutting process with deep-point blades. Recognizing these problems allows for timely intervention and improved cutting performance. Below are common complications along with their respective solutions:

- Rough Edges:

Rough edges are often a result of dull blades or incorrect cutting speed. To remedy this, ensure that the blade is sharp and adjust the speed according to material type and thickness. Utilizing a slower cutting speed may yield cleaner edges. - Excessive Material Fraying:

Fraying typically occurs due to improper blade choice or insufficient pressure. Selecting the appropriate blade for the material and providing consistent, even pressure can minimize fraying. - Inconsistent Cut Depth:

Inconsistent cutting can be caused by uneven material thickness or insufficient blade stability. It is crucial to check the material for uniformity before cutting and to ensure that the workpiece is securely clamped to prevent movement. - Burning or Melting of Material:

This issue often arises when cutting through thermoplastic materials with excessive speed or pressure. Lowering the feed rate and ensuring proper ventilation can help reduce overheating and material deformation.

Adjusting Techniques Based on Material Thickness Variations

Different material thicknesses demand adjustments in cutting techniques to achieve optimal results. Recognizing the appropriate settings and methods for varying thicknesses is essential for successful cutting. The following guidelines can assist in adapting your approach:

- For Thinner Materials (up to 1/8 inch):

Utilize a higher cutting speed and lighter pressure to prevent damage while ensuring a smooth cut. - For Medium Thickness Materials (1/8 inch to 1/4 inch):

A moderate cutting speed with balanced pressure is advisable. This allows for both control and efficiency without sacrificing cut quality. - For Thicker Materials (over 1/4 inch):

Employ a slower cutting speed and increased pressure. Ensure the blade has ample time to penetrate the material effectively for a clean cut.

Tips for Achieving Cleaner Cuts with Thicker Materials

Achieving cleaner cuts in thicker materials requires specific techniques and considerations to ensure precision and quality. Implementing the following tips can significantly enhance cut quality:

- Use the Right Blade:

Selecting a blade specifically designed for thicker materials will result in better performance and cleaner cuts. - Maintain Consistent Pressure:

Applying steady, even pressure throughout the cutting process will facilitate a smoother cut and prevent blade binding. - Utilize a Guide or Jig:

Employing a cutting guide or jig can help maintain a straight line and minimize deviations during the cutting process. - Regularly Inspect and Maintain Blades:

Keeping blades sharp and well-maintained is crucial. Regular inspections can help identify wear and ensure optimal cutting performance.

Advanced Techniques for Professionals

The use of deep-point blades extends beyond basic cutting; for experienced users, mastering advanced techniques can significantly enhance performance on thicker materials. This section delves into sophisticated methods and modifications that can improve efficiency and outcomes in professional applications, as well as exploring innovative uses that transcend traditional cutting techniques.

Advanced Cutting Methods

For professionals utilizing deep-point blades, advanced cutting methods can facilitate greater precision and adaptability. These techniques leverage the unique design of the blades to optimize performance.

One effective method is the multi-pass cutting technique, where multiple shallow passes are made rather than attempting to cut through the material in a single pass. This approach reduces strain on the blade and minimizes the risk of material distortion. Additionally, users can implement the oscillating cut technique, which involves a slight back-and-forth motion during the cut to enhance blade engagement and reduce friction.

Modifications to Enhance Performance

Modifying deep-point blades can yield improved performance, especially when cutting through thicker materials. Consider the following enhancements:

Blade Sharpening

Regular sharpening using a specialized honing tool can maintain the blade’s sharpness, ensuring clean cuts and reducing wear on the blade.

Custom Tip Geometry

Altering the blade tip to a more acute angle can facilitate easier penetration into thicker materials, allowing for smoother initial cuts.

Use of Lubricants

Applying suitable cutting lubricants can reduce friction and heat buildup, prolonging the life of the blade while ensuring smoother cutting action.

These modifications can lead to enhanced efficiency and precision, reducing the likelihood of blade breakage or material damage.

Innovative Uses of Deep-Point Blades

Deep-point blades are not limited to their conventional applications; innovative uses have emerged across various fields. Some noteworthy applications include:

Textile Cutting

In the fashion industry, deep-point blades can precisely cut layered fabrics, allowing designers to achieve intricate patterns and designs without fraying edges.

Foam and Insulation Creation

For construction and packaging industries, deep-point blades can effectively cut through thick foam and insulation materials, ensuring a perfect fit for various applications.

Crafting and DIY Projects

Hobbyists have discovered that deep-point blades are ideal for creating detailed designs in wood, plastic, and other substrates, fostering creativity in crafting.

By exploring these innovative applications, users can maximize the utility of deep-point blades well beyond their traditional cutting roles.

Last Point

In summary, mastering the use of deep-point blades for thicker materials not only enhances cutting precision but also opens up a realm of possibilities for innovative projects across various industries. By adhering to best practices in preparation, cutting techniques, and maintenance, users can significantly improve their results and extend the life of their tools. Embrace the versatility of deep-point blades, and take your crafting to the next level with ease and professionalism.