How to Solve Print Then Cut Calibration Issues reveals essential strategies to achieve optimal calibration for your print then cut machine, ensuring superior results. This process is vital for anyone looking to enhance their crafting projects, as accurate calibration directly influences the quality of the final cuts and prints.

Users often encounter a variety of calibration challenges that can lead to misalignment and subpar output. By understanding common issues and learning effective troubleshooting techniques, crafters can significantly improve their experience and results.

Understanding Print Then Cut Calibration

Calibration is a critical step in the print then cut process, ensuring that printed designs align perfectly with the cutting blade. Accurate calibration can significantly enhance the quality of the final output, preventing misalignments that could lead to waste and frustration. Understanding how to address calibration issues is essential for users aiming to achieve professional results in their projects.Calibration issues commonly encountered by users include misalignment of printed images and cut lines, inconsistent cutting depth, and discrepancies in color matching.

These problems can arise from various factors, such as printer settings, paper type, and even the cutting machine’s hardware. Properly addressing these calibration challenges is vital for achieving a seamless print then cut experience.

Impact of Calibration on Final Output Quality

Effective calibration is essential for the quality of print then cut projects. It directly influences how well the cutting blade follows the intended design, which in turn affects the overall appearance and usability of the final product. Calibration issues can lead to poor alignment, resulting in uneven cuts or incomplete designs. Key aspects of how calibration impacts output quality include:

- Precision: Accurate calibration allows the cutting blade to follow the printed design closely, ensuring that edges are clean and shapes are defined.

- Consistency: Properly calibrated settings help maintain uniform cutting depth across multiple projects, producing consistent results every time.

- Visual Appeal: Calibration affects color registration, ensuring that colors print accurately and vibrant, enhancing the overall aesthetics of the final piece.

In summary, an understanding of print then cut calibration not only optimizes the operational efficiency of the cutting process but also plays a vital role in producing high-quality, professional-looking products. Calibration is not merely a technical requirement; it is a foundation upon which the success of print then cut projects is built.

“Calibration is the backbone of precision in print then cut processes, ensuring that every design is executed flawlessly.”

Common Print Then Cut Calibration Problems

Print Then Cut machines are invaluable tools for crafters, enabling precise cutting of printed designs. However, users often encounter calibration issues that can hinder their projects. Understanding these common problems is essential for achieving accurate results and enhancing the user experience. Calibration problems can arise from various factors, leading to misalignment and inaccuracies that may frustrate users.Misalignment during the calibration process is a frequent issue that can compromise the quality of the final product.

There are several typical scenarios where misalignment may occur, often due to user error or equipment malfunction. Users may notice that their cuts are slightly off from the printed design, resulting in a less polished appearance and wasted materials. Such discrepancies can stem from a misalignment of the print head or improper loading of the material into the machine.

Examples of Misalignment During Calibration

Misalignment can manifest in several ways during the Print Then Cut process. To better understand this issue, consider the following examples:

- Shifted Cut Lines: Users might find that the cut lines do not align with the printed images. This can happen if the registration marks are not detected properly, leading the machine to cut in the wrong position.

- Offset Cuts: An offset may occur if the machine is not calibrated to recognize the print area accurately. This can result in the cut being placed too high, too low, or to the side of the intended design.

- Inconsistent Margins: Users may experience varied margins around their prints, which can be a result of uneven printing or calibration settings that are not standardized across different materials or designs.

Calibration errors can also lead to inaccurate cuts and prints due to several underlying causes. Understanding these causes can significantly aid in troubleshooting and resolving issues effectively.

Potential Causes of Inaccurate Cuts and Prints

When calibrating Print Then Cut machines, various factors can contribute to inaccuracies that affect the overall performance. Some of the most common causes include:

- Improper Material Loading: If the material is not loaded correctly, it can shift during the cutting process, leading to misalignments.

- Dirty Sensors: Dust or debris on the machine’s sensors can interfere with the detection of registration marks, resulting in incorrect cuts.

- Software Settings: Incorrect settings within the cutting software may lead to discrepancies between the design and the actual output, affecting alignment and precision.

- Printer Calibration: If the printer itself is not calibrated properly, it may produce images that do not match the intended sizing or alignment.

- Environmental Factors: Variations in humidity and temperature can affect the material properties and the machine’s operation, potentially leading to inconsistent results.

By identifying these common calibration problems and their causes, users can take proactive steps to ensure that their Print Then Cut projects are executed with precision and accuracy.

Step-by-Step Calibration Procedures

Calibration is a critical process for ensuring accuracy and precision in Print Then Cut machines. Proper calibration allows for flawless alignment between printed images and cutting paths, enhancing the overall quality of the crafted items. This guide provides a systematic approach to calibrating your Print Then Cut machine, along with adjustments to settings for optimal performance.

Calibration Steps for Print Then Cut Machines

To achieve accurate calibration, follow these steps meticulously. Each step is essential for ensuring that the machine operates effectively and produces the best results.

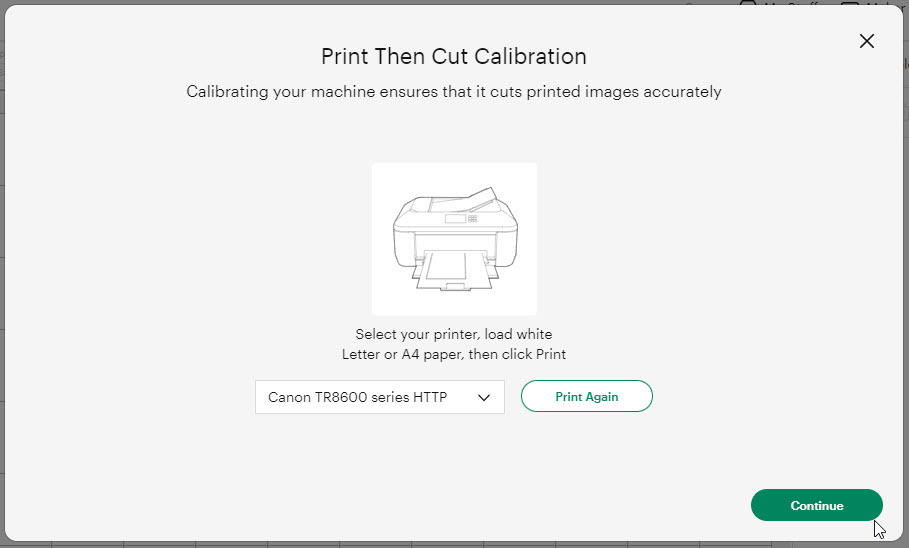

Prepare the Printer and Material

Ensure that the printer is loaded with the correct paper type and that the ink levels are sufficient.

- Use high-quality materials that are compatible with your machine for best results.

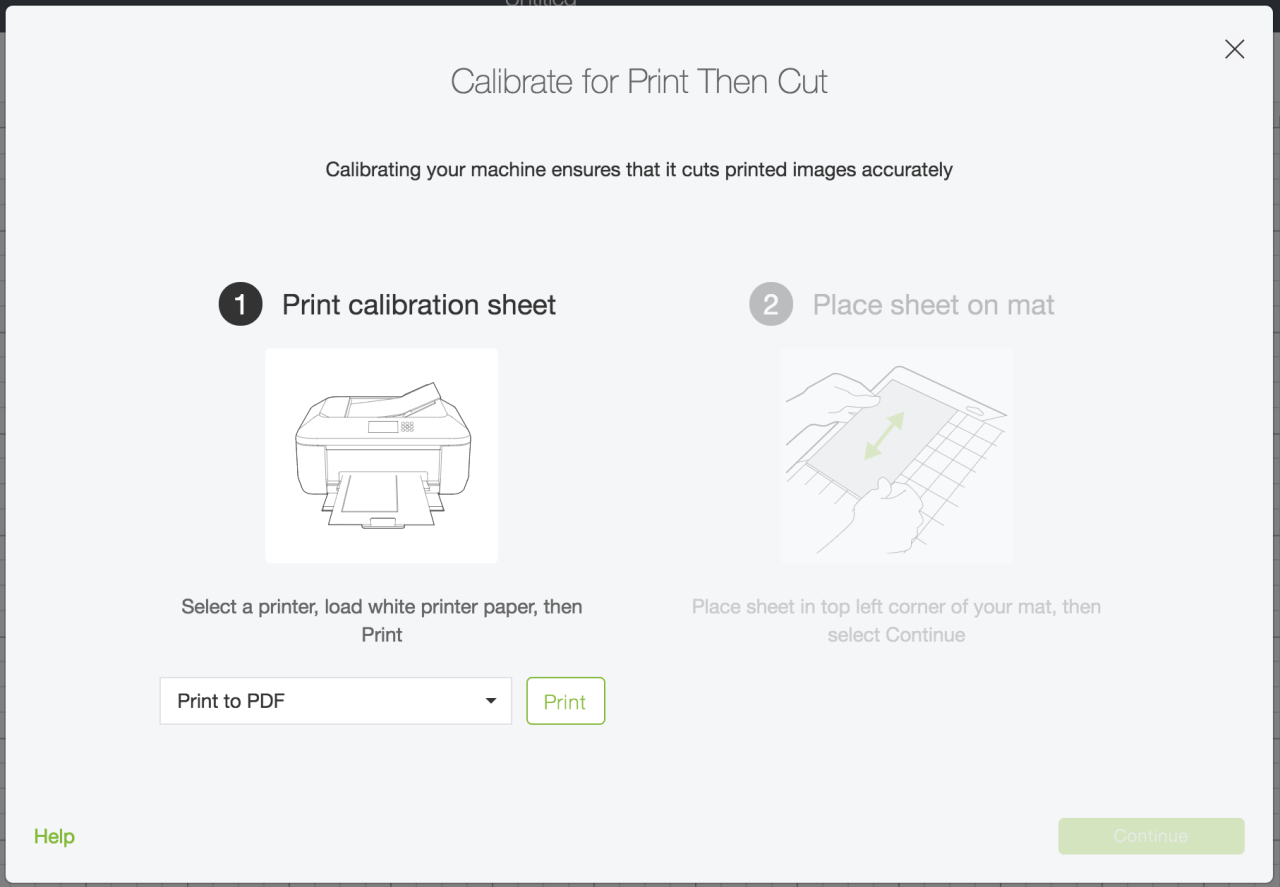

- Print Calibration Sheet

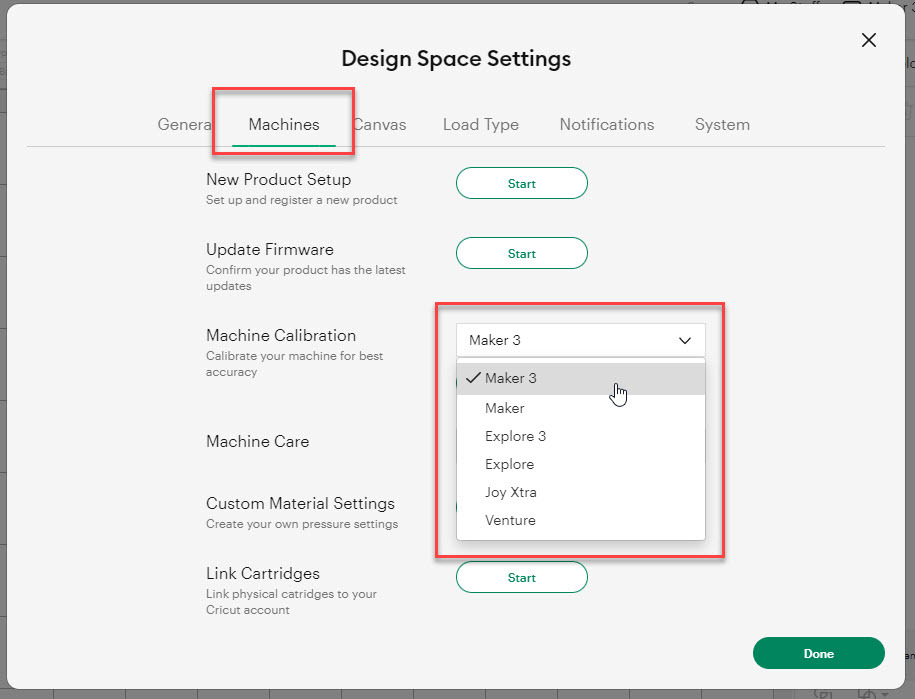

Access the calibration settings on your machine’s software.

- Print the calibration sheet that the software generates, which typically includes alignment marks and test cuts.

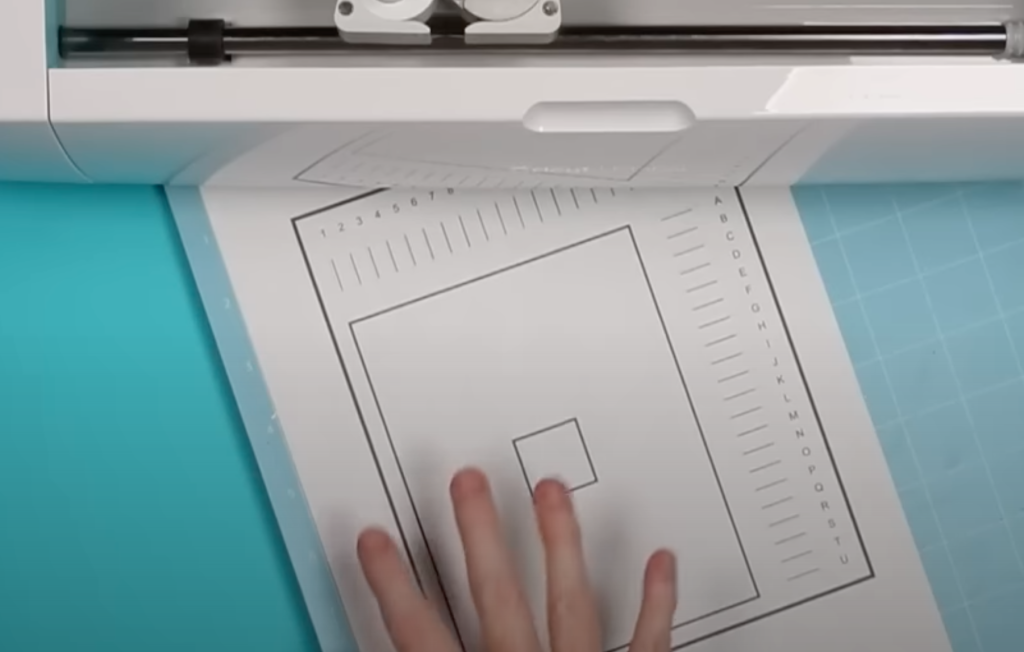

- Align the Calibration Sheet

Once printed, place the calibration sheet on the cutting mat.

- Ensure it is aligned properly within the cutting machine’s designated area.

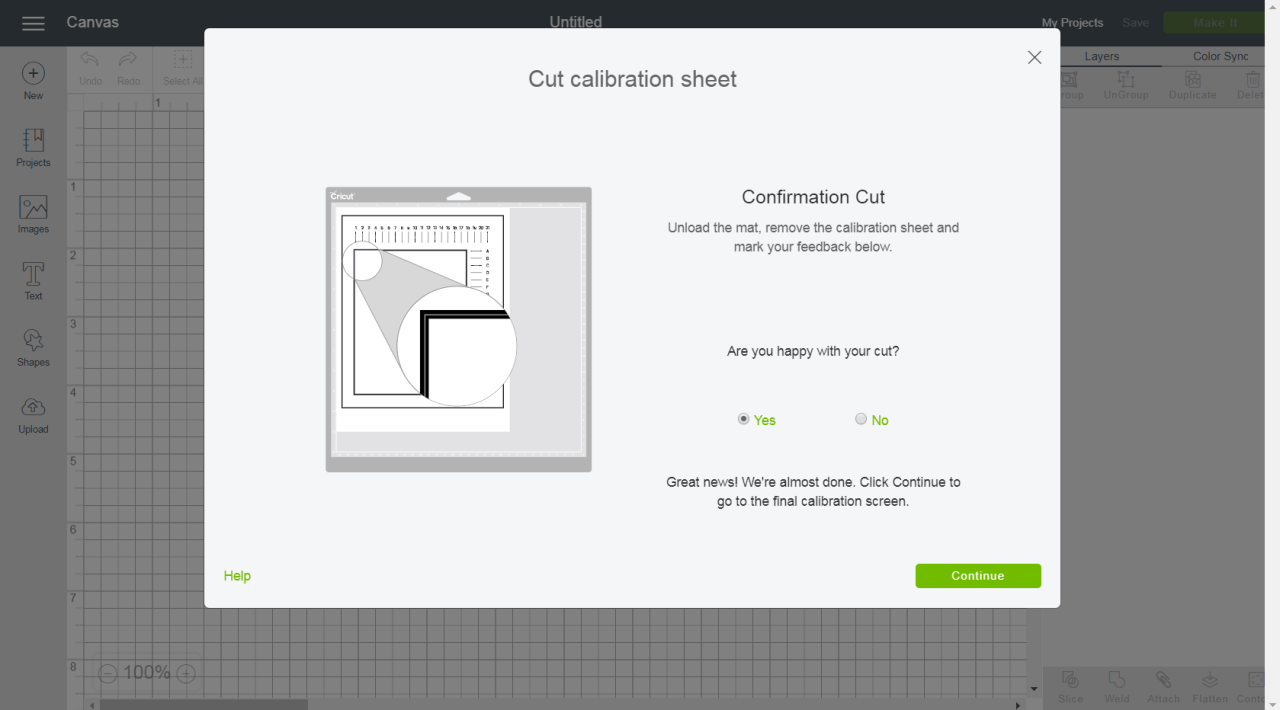

- Scan the Calibration Sheet

Use the Print Then Cut feature to scan the calibration sheet.

- The machine will analyze the alignment marks to determine any discrepancies.

- Adjust Calibration Settings

Based on the scanned data, adjust the calibration settings accordingly.

- This may involve fine-tuning the X and Y axis settings to ensure that the cuts are perfectly aligned with the printed images.

- Perform Test Cuts

Execute a test cut using a simple shape or design.

- Analyze the results to determine if further adjustments are necessary.

- Save Calibration Settings

Once satisfied with the alignment, save the calibration settings in the machine’s memory.

Ensure to document the settings for future reference.

Adjusting Settings for Optimal Calibration

Perfecting the calibration process often requires detailed adjustments to various settings. Here are crucial factors to consider:

Cut Pressure and Speed

Adjusting the pressure and speed settings can greatly influence the cutting accuracy. Lower speeds are often recommended for intricate designs.

Blade Depth

Ensure that the blade depth is set correctly according to the material thickness. Incorrect blade depth can lead to tearing or incomplete cuts.

Sensor Calibration

Regularly check and recalibrate the sensors that read the registration marks on the printed sheet to maintain accuracy.

Calibration Checklist

To ensure that all calibration steps have been completed, utilize the following checklist:

- [ ] Printer loaded with correct paper type.

- [ ] Sufficient ink levels checked.

- [ ] Calibration sheet printed correctly.

- [ ] Calibration sheet aligned properly.

- [ ] Calibration sheet scanned by the machine.

- [ ] Calibration settings adjusted based on scan results.

- [ ] Test cuts performed and analyzed.

- [ ] Calibration settings saved and documented.

Following these structured steps and guidelines will help ensure that your Print Then Cut machine operates with precision, producing high-quality results in every project.

Troubleshooting Calibration Issues

Calibration issues can significantly impact the quality of your print then cut projects. Addressing these problems promptly not only improves your results but also enhances your overall crafting experience. Understanding the common calibration issues and their solutions is essential for any user looking to achieve precise and accurate cuts.

Methods for Troubleshooting Misalignment Problems

Misalignment during the print then cut process can lead to unsatisfactory results. To effectively troubleshoot misalignment problems, consider the following methods:

1. Check the Printer Settings

Ensure the printer settings are correctly configured for the media type being used. Incorrect settings can lead to disproportionate scaling.

2. Recalibrate the Machine

Follow the manufacturer’s guidelines to perform a recalibration of the cutting machine. This process should be completed regularly to maintain accuracy.

3. Confirm Registration Marks Alignment

Before cutting, examine if the registration marks printed are clear and properly aligned. Smudged or faint marks can result in misreads.

4. Use High-Quality Materials

Low-quality paper or vinyl may warp or shrink, affecting alignment. Opt for high-quality materials to aid in accuracy.

5. Adjust Cut Settings

Fine-tuning the blade depth and cut speed can impact how well the machine reads the registration marks.

Procedures for Rectifying Color Registration Errors

Color registration errors can compromise the aesthetic of your designs. To rectify these errors, follow these procedures:

1. Use Accurate Color Profiles

Ensure that the correct color profiles are selected in your design software, matching the printer and cutting machine specifications.

2. Calibrate Printer and Cutter

Regularly calibrate both the printer and the cutting machine to ensure they are in sync, which is crucial for registration accuracy.

3. Print Test Swatches

Print small test swatches before committing to larger projects. This allows you to confirm that colors are printing correctly without wasting materials.

4. Adjust Material Feed

Check that the media is properly fed into the printer, as any slippage can lead to color misalignment.

5. Clean the Printer Heads

Regular maintenance, including cleaning the printer heads, can prevent color issues caused by blockages or residue.

Flowchart for Common Calibration Issues and Their Solutions

Utilizing a flowchart can simplify the troubleshooting process. Below is a structured Artikel illustrating common calibration issues with corresponding solutions:

| Calibration Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Misalignment | Incorrect printer settings, faulty calibration | Check printer settings; recalibrate the cutting machine. |

| Color Registration Errors | Wrong color profiles, misaligned material | Use correct color profiles; check media feed. |

| Faint Registration Marks | Low-quality ink, dirty printer heads | Use high-quality ink; clean printer heads. |

| Inconsistent Cuts | Worn blade, improper material thickness | Replace the blade; adjust cut settings based on material. |

Tools and Resources for Calibration

Accurate calibration is essential for optimal performance in print then cut applications. Utilizing the right tools and resources can help streamline the calibration process, ensuring precise results for your projects. In this section, we will explore various tools and software options that support effective calibration, as well as where to find helpful materials and guides online.

Calibration Tools

Several tools assist in achieving accurate calibration in print then cut processes. These tools can range from physical instruments to software applications that streamline setup and adjustments.

- Calibration Ruler: A calibration ruler is specifically designed to measure the alignment and distance accurately. It helps ensure that your cuts align perfectly with the printed designs.

- Print Then Cut Test Sheets: These sheets often come with calibration marks that assist in checking your machine’s alignment. They can be printed and used to evaluate the accuracy of the cut settings.

- Alignment Tools: Many cutting machines come with built-in alignment tools that guide you through the calibration process. Familiarizing yourself with these can greatly improve accuracy.

Software Options for Calibration

There are several software options available to facilitate the calibration process, enhancing accuracy and efficiency. These applications cater to various operating systems and provide user-friendly interfaces for calibration tasks.

- Design Software: Software like Cricut Design Space and Silhouette Studio includes calibration settings that allow users to adjust cutting parameters easily. These applications often provide step-by-step guides to assist in the calibration process.

- Calibration Software: Dedicated calibration software helps users precisely adjust their settings based on the machine’s specifications and the materials being used.

- Firmware Updates: Keeping your machine’s firmware updated can enhance calibration accuracy. Manufacturers often release updates that improve overall functionality and alignment capabilities.

Finding Resources Online

Accessing quality resources online can significantly enhance your understanding and execution of print then cut calibration. A wealth of information is readily available to help users address calibration-related challenges.

- Manufacturer Websites: Most cutting machine manufacturers maintain comprehensive support sections on their websites, offering guides, tutorials, and troubleshooting tips tailored to their specific models.

- YouTube Tutorials: Video tutorials are invaluable resources for visual learners. Many content creators provide in-depth calibration guides and demonstrations that can simplify complex processes.

- Online Forums and Communities: Engaging with online communities, such as Facebook groups or Reddit forums, can provide insights and shared experiences from other users who have faced similar calibration issues.

Utilizing the right tools and resources is crucial in achieving precise calibration outcomes for your print then cut projects.

Best Practices for Maintaining Calibration

Maintaining proper calibration of your print then cut equipment is essential for achieving consistent and high-quality results. Calibration ensures that printed images align perfectly with the cutting lines, minimizing waste and maximizing efficiency. Regular upkeep of your equipment not only extends its lifespan but also enhances its performance.To ensure your print then cut equipment remains consistently calibrated over time, consider implementing the following best practices.

These practices help to prevent calibration drift and ensure reliable operation.

Regular Calibration Checks

Consistently checking the calibration of your equipment is vital in maintaining accuracy. Incorporating routine checks into your workflow can help identify issues early on.

- Perform a calibration check before starting a new project, especially if the printer or cutter has been unused for an extended period.

- Frequent small projects can help maintain calibration, as regular use keeps the equipment in optimal working condition.

- Document calibration results to track any discrepancies over time, which can indicate potential maintenance needs.

Proper Storage and Environmental Control

The environment where the equipment is stored can significantly affect calibration. Consider the following storage practices to maintain optimal conditions:

- Store equipment in a stable environment with controlled temperature and humidity to prevent material expansion or contraction.

- Keep the printer and cutter free from dust and debris by using protective covers when not in use.

- Avoid direct sunlight exposure, which can cause fading or damage to sensitive components.

Scheduled Maintenance Practices

Implementing a scheduled maintenance routine is crucial for ongoing calibration. The following table compares different maintenance schedules and their impact on calibration:

| Maintenance Frequency | Recommended Actions | Impact on Calibration |

|---|---|---|

| Daily | Clean print heads, check alignment | Ensures optimal print quality and cuts |

| Weekly | Inspect blades, check for wear and tear | Prevents calibration drift due to tool degradation |

| Monthly | Run a full calibration procedure, update software | Restores precision and accuracy |

| Quarterly | Deep cleaning, inspect mechanical components | Extends equipment life and maintains baseline calibration |

Utilization of Calibration Tools and Software

Taking advantage of calibration tools and software can streamline the calibration process. Using reliable software can assist in monitoring calibration status and suggest adjustments when necessary. Regular updates to the software also ensure access to the latest calibration features and improvements.By integrating these best practices into your workflow, you can maintain optimal calibration of your print then cut equipment, thereby enhancing efficiency and product quality over time.

User Experiences and Case Studies

User experiences with print then cut calibration can provide invaluable insights into the common challenges faced by users and the solutions they have implemented. Understanding these real-world scenarios can assist others in refining their calibration processes and achieving better results.Feedback from the community reveals a variety of calibration challenges, ranging from alignment issues to inconsistent color output. Users have documented their experiences, showcasing solutions that have led to significant improvements.

This shared knowledge not only helps in troubleshooting but also fosters a sense of community where users can learn from each other’s successes and difficulties.

User Experiences with Calibration Challenges

Many users have reported encountering initial calibration difficulties, particularly with alignment issues. For example, a user named Jenna experienced consistent misalignment of her prints, leading to poorly cut designs. After exploring various adjustments, she discovered that recalibrating her printer settings and using high-quality paper significantly improved her outcomes.Another user, Tom, faced color discrepancies between his designs on screen and the printed result.

Through trial and error, Tom learned the importance of accurately setting the color profile on both his printer and cutting machine. By aligning these settings, he achieved a more precise color match, resulting in better quality projects.

Several case studies highlight successful calibration adjustments and the transformative effects they had on users’ projects. One notable case involved a small business owner, Sarah, who struggled with inconsistent cutting margins. After rigorous testing and adjustments to her calibration settings, Sarah documented her process, which included:

- Adjusting the registration marks on her printouts

- Regularly cleaning the cutting blade and mat

- Testing cuts on scrap material before final projects

As a result, Sarah reported a dramatic improvement in her production efficiency and product quality, which ultimately increased customer satisfaction.

Users have shared their experiences with various calibration techniques, emphasizing the importance of testing and iteration. Key techniques that have garnered positive feedback include:

- Frequent calibration checks to ensure consistent results over time.

- Utilizing the manufacturer’s calibration guidelines as a baseline for setup.

- Taking advantage of community forums and resources for tips and troubleshooting advice.

- Incorporating software updates as part of regular maintenance to enhance functionality.

These techniques not only simplify the calibration process but also empower users to achieve consistent and high-quality results in their print then cut projects.

“Calibration is not just a one-time task; it’s an ongoing process that requires attention to detail and frequent adjustments for optimal performance.”

User testimonial

Closing Notes

In conclusion, mastering the calibration process is crucial for achieving precision in print then cut projects. By applying the best practices and troubleshooting methods discussed, users can overcome calibration issues, enhancing both their skills and end products. Embracing these techniques will pave the way for a more enjoyable and successful crafting experience.