How to Use the Weld Tool to Combine Shapes is an essential guide for designers looking to enhance their creative projects. This powerful tool serves as a bridge between individual shapes, allowing for seamless integration and innovative design solutions. By mastering the Weld Tool, users can transform their projects, bringing a new level of sophistication and creativity.

Understanding the purpose and functionality of the Weld Tool is crucial for effective design. It enables the combination of various shapes, streamlining the design process and offering flexibility in creating unique visual elements. In this guide, we will explore the steps to prepare shapes, techniques to employ the Weld Tool, and common troubleshooting strategies, all aimed at empowering users to unleash their creativity.

Understanding the Weld Tool

The Weld Tool is an essential feature in various design software applications that allows users to seamlessly combine multiple shapes into a single, unified entity. This tool is vital for creating complex designs, enhancing both the aesthetic appeal and structural integrity of graphical elements. By using the Weld Tool, designers can eliminate overlaps and ensure that the final output is cohesive and professional in appearance.The primary purpose of the Weld Tool is to streamline the design process by simplifying the manipulation of shapes.

When multiple shapes are combined, designers can avoid the complications often associated with individual elements, such as misalignment or unintended gaps. Effective shape combination is crucial for achieving clean lines and smooth transitions in designs, which is particularly important in industries such as graphic design, architecture, and product design.

Common Software Featuring the Weld Tool

The Weld Tool is commonly found in several popular design software programs, each offering unique functionalities tailored to different design needs. Understanding where to find this tool and how it operates within different environments can significantly enhance a designer’s workflow. Below are some of the notable software applications that include the Weld Tool:

- Adobe Illustrator: A leading vector graphics editor, Illustrator features the Weld Tool within its Pathfinder panel, facilitating the combination and manipulation of vector shapes with precision.

- CorelDRAW: This graphic design software provides the Weld Tool through its Shape Tool feature, allowing users to merge objects effortlessly while maintaining design integrity.

- Inkscape: As an open-source vector graphics editor, Inkscape includes a Weld feature that enables users to join paths and shapes, making it accessible for designers on various budgets.

- Silhouette Studio: Frequently used for crafting and vinyl cutting, this software incorporates the Weld function to prepare designs for cutting machines, ensuring that shapes are properly combined before production.

The integration of the Weld Tool in these software applications emphasizes its importance in modern design practices. Designers should familiarize themselves with the specific functionalities and potential applications of the Weld Tool within their selected software to maximize efficiency and creativity in their projects.

The effective use of the Weld Tool not only simplifies the design process but also enhances the visual appeal and structural quality of the final product.

Preparing Shapes for Welding

Before utilizing the Weld Tool, it is crucial to prepare the shapes appropriately to ensure successful and precise welding results. This preparation process involves selecting and aligning the shapes effectively, thereby maximizing the functionality of the Weld Tool. By following the correct procedures, users can efficiently merge various shapes and create intricate designs that meet their project requirements.In the context of preparing shapes for welding, it is essential to consider the selection of the shapes that will be combined.

The Weld Tool can effectively combine a variety of shapes, including both basic geometric forms and more complex designs. By understanding which shapes can be used and how to align them properly, users can enhance the overall outcome of their projects.

Steps to Select Shapes for Welding

Proper selection of shapes is the first step in the welding process. Begin by highlighting the shapes you wish to combine. This process can typically be accomplished using the selection tool available within your design software. Here are the steps to follow:

1. Open the Design Software

Navigate to the workspace where your shapes are located.

2. Select Shapes

Utilize the selection tool to click on each shape you wish to combine. Hold the ‘Shift’ key to select multiple shapes simultaneously.

3. Group Shapes (Optional)

If desired, group the selected shapes for easier manipulation. This can help in managing complex designs.

Common Shape Types for Combining

The Weld Tool accommodates various types of shapes, enabling a wide range of design possibilities. Below are common shape types that can be effectively combined:

Basic Geometric Shapes

Circles, squares, triangles, and rectangles are foundational shapes that can be easily welded together.

Complex Shapes

Custom shapes, polygons, and paths created through design software can also be utilized with the Weld Tool.

Text Shapes

Individual letters or entire words converted into paths can be welded to form cohesive text designs.

Tips for Aligning Shapes for Optimal Welding Results

Achieving optimal results when using the Weld Tool requires careful alignment of the selected shapes. Proper alignment ensures that the shapes combine seamlessly and reduces the likelihood of gaps or misalignments. Consider the following tips:

Use Alignment Tools

Most design software provides alignment tools that help center or distribute shapes evenly. Utilize these tools to maintain balance in your design.

Snap to Grid

Enable the snap-to-grid feature to assist in aligning shapes accurately. This feature helps to position shapes precisely according to your design layout.

Check Overlapping Areas

Ensure that the areas where shapes overlap are sufficient for the Weld Tool to create a solid bond. Aim for overlapping sections that are neither too large nor too small.

Proper preparation and alignment of shapes are essential for successful welding. Ensuring that shapes are selected and aligned correctly allows for smoother and more effective merging.

Using the Weld Tool

The Weld Tool is an essential feature that allows users to combine multiple shapes into a single cohesive design. Understanding how to effectively utilize this tool can significantly enhance your design capabilities, facilitating the creation of intricate patterns and customized designs. This section will provide a detailed step-by-step guide on accessing and using the Weld Tool, as well as an overview of the key settings available for optimal use.

Accessing and Using the Weld Tool

To successfully utilize the Weld Tool, follow these structured steps:

1. Open your design software

Launch the software where you intend to create your design, ensuring all necessary updates are installed for the best performance.

2. Create or import shapes

Start by either creating new shapes using the shape tools provided or importing existing shapes from other files or sources.

3. Select the shapes to combine

Use the selection tool to highlight the shapes you want to weld. Ensure that they are overlapping or in close proximity for the weld function to operate effectively.

4. Locate the Weld Tool

Navigate to the main menu or toolbar, and look for the ‘Weld Tool’ icon, typically represented by a welding symbol or a similar graphic.

5. Activate the Weld Tool

Click on the Weld Tool icon to activate it. The software will process the selected shapes and create a unified shape.

6. Review the result

Observe the newly formed shape for any inconsistencies or required adjustments. If needed, edits can be made using other tools available in the software.The above steps are crucial for ensuring that shapes are combined accurately, allowing for seamless design creation.

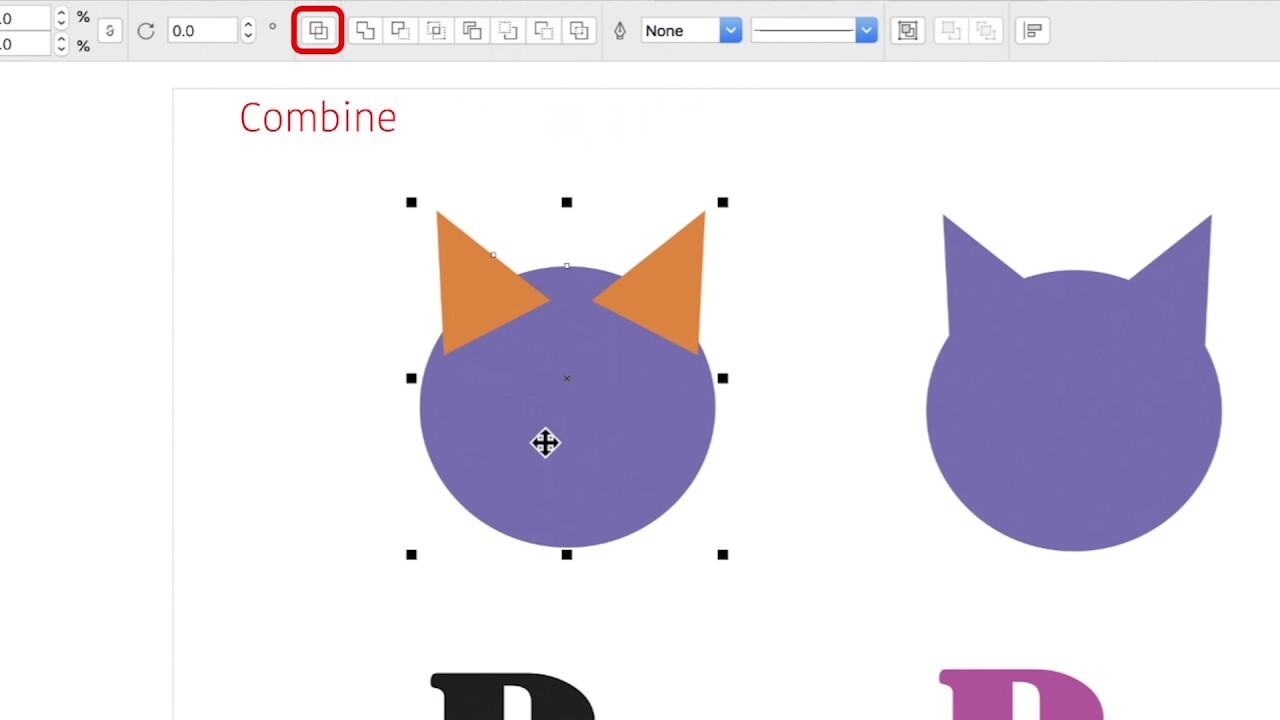

Combining Two Shapes Using the Weld Tool

Combining shapes using the Weld Tool can be demonstrated through a simple example. Consider two overlapping circles that you wish to merge into a single entity.

- Create two circles of different sizes positioned so that they intersect.

- Follow the steps Artikeld in the previous section to select both circles.

- Activate the Weld Tool.

After activation, the two circles will merge, creating a new shape that reflects the overlapping areas. The resulting shape will retain a smooth Artikel, representing the combined form accurately.

Key Settings Available in the Weld Tool

Understanding the settings available in the Weld Tool can further enhance the efficiency of shape combination. Below are the key options you may encounter:

Overlap Recognition

This setting determines how much of the shapes must overlap in order to be combined. Adjusting this can help in merging shapes that are barely touching.

Precision Control

This option allows users to refine the accuracy of the weld. Higher precision settings will result in a cleaner weld line, especially for complex shapes.

Style Options

Users may be able to choose between different welding styles, such as rounded edges or sharp corners, depending on the design requirements.

Undo/Redo Functionality

This feature enables users to revert changes or reapply them, providing flexibility when experimenting with different combinations.These settings empower users to customize their welding process, leading to better design outcomes.

“The Weld Tool transforms individual shapes into a cohesive design, enhancing creativity and efficiency in the design process.”

Exploring Different Welding Techniques

In design projects, using the weld tool effectively can vary depending on the shapes and the desired outcome. Understanding the diverse welding techniques available is crucial for achieving precise results that meet design specifications. The right technique can enhance the overall appearance and functionality of the project, ensuring that the combined shapes serve their intended purpose effectively.Different welding techniques are employed based on the complexity of the shapes and the specific requirements of the design.

Each technique has unique characteristics that can affect the final output. Below are several welding techniques along with their descriptions and appropriate use cases:

Types of Welding Techniques

When combining shapes in design projects, choosing the correct welding technique is essential. Here are some commonly used techniques:

- Standard Welding: This method merges overlapping shapes seamlessly, creating a unified design. It is ideal for basic shapes that require a smooth finish.

- Intersecting Welding: This technique joins shapes that intersect at a specific point. It is particularly useful for creating complex geometries or intricate designs.

- Layered Welding: With this approach, shapes are stacked and welded in layers. This method is beneficial for creating depth in designs, such as layered text or multi-dimensional objects.

- Negative Space Welding: This technique utilizes the spaces between shapes to create a cohesive design. It is ideal for artistic projects where the negative space plays a crucial role in the overall composition.

The differences between welding and other shape-combining methods such as grouping or merging are significant. While grouping simply organizes shapes without altering their individual attributes, welding combines them into a single entity, which can affect later modifications. Merging shapes may result in overlaps being visible, whereas welding ensures a clean intersection, providing a more polished look.

When to Use Each Welding Technique

Selecting the appropriate welding technique is vital for achieving the best results. Here are examples of when to utilize each technique effectively:

- Standard Welding: Use this technique when designing logos or icons where a seamless appearance is essential for clarity.

- Intersecting Welding: This is suitable for creating detailed illustrations or patterns that require precision in shape intersections.

- Layered Welding: Ideal for crafting layered greeting cards or scrapbooking projects where depth and texture are desired.

- Negative Space Welding: This technique works well in artistic designs where the interplay of shapes and spaces is the focal point, such as in modern art or signage.

By understanding these techniques and their applications, designers can better navigate the complexities of shape welding to enhance their creative projects.

Troubleshooting Common Issues

When using the Weld Tool to combine shapes, users may occasionally encounter issues that can hinder the desired outcome. Understanding these common problems and their resolutions is crucial for a smoother workflow and effective shape manipulation. Being aware of these obstacles not only saves time but also enhances the overall user experience when utilizing design software.

Identification of Common Problems

Several issues may arise while employing the Weld Tool. Recognizing these problems is the first step in troubleshooting effectively. Some of the most common issues include overlapping shapes not welding properly, unexpected gaps in the weld, and the tool being unresponsive to certain shape combinations. To address these issues, consider the following strategies:

- Ensure that the shapes are completely overlapped. Incomplete overlaps may cause the welding process to fail.

- Check for any hidden layers or shapes that might interfere with the weld. Select all elements to confirm no overlapping issues exist.

- Adjust the color or stroke of the shapes, as certain settings may prevent the Weld Tool from executing properly.

Best Practices for Avoiding Errors

Adopting best practices during the welding process can significantly reduce the likelihood of errors. Following these guidelines enhances the efficiency of the Weld Tool and prevents common pitfalls:

- Regularly save your work to avoid losing progress if issues arise during the welding process.

- Utilize the ‘Preview’ option, if available, to visualize the outcome before finalizing the weld.

- Group shapes prior to welding to maintain organization and streamline the process.

Compatibility Issues with Certain Shapes

Certain shapes may present compatibility challenges when using the Weld Tool. Understanding which shapes work best together is essential for successful welding. Shapes with complex paths or intricate details, such as those created using the pen tool, may not weld seamlessly with simpler geometric shapes. Additionally, non-standard shapes may require tweaking and adjustments to ensure compatibility. To improve compatibility, consider the following techniques:

- Simplify complex shapes by converting them to basic Artikels or reducing the number of points where possible.

- Experiment with different shape combinations and utilize the software’s diagnostics to identify compatibility issues.

- Consult the software’s documentation or user forums for specific shape compatibility recommendations, as community input can provide valuable insights.

“Being proactive in identifying and resolving issues while using the Weld Tool fosters a more efficient design process and enhances creativity.”

Practical Applications of the Weld Tool

The Weld Tool is an invaluable feature in design software, providing designers with the capability to combine shapes seamlessly. This tool not only enhances design efficiency but also expands creative possibilities. Understanding the practical applications of the Weld Tool can significantly benefit various industries by streamlining workflows and improving final outcomes.Utilizing the Weld Tool can be pivotal in numerous design scenarios, such as creating intricate logos, custom shapes for product packaging, or detailed artwork for signage.

By combining multiple shapes into a single cohesive design, users can achieve both aesthetic and functional purposes effectively. The following sections illustrate specific industries that benefit from the Weld Tool.

Industries Benefiting from the Weld Tool

The Weld Tool finds its application across diverse industries, allowing designers to simplify complex projects. Industries that frequently utilize this feature include:

- Graphic Design: Designers create logos and marketing materials by combining various elements, ensuring a polished and professional appearance.

- Manufacturing: In product design, the Weld Tool allows for the creation of prototypes and tools that require precise shapes for functionality.

- Fashion Design: Designers can combine fabric shapes and patterns, resulting in unique garment designs that stand out in the market.

- Architecture: Architects utilize the Weld Tool to create complex structural models and layouts that require precision and artistry.

- Crafting and DIY Projects: Hobbyists and crafters use this tool to create custom designs for various projects, from home decor to personalized gifts.

Comparison of Weld Tool and Manual Shape Combination Methods

When considering the efficiency of design processes, comparing the Weld Tool to manual shape combination methods is essential. The table below Artikels the advantages of using the Weld Tool:

| Feature | Weld Tool | Manual Shape Combination |

|---|---|---|

| Speed of Use | Fast, with automated processes for combining shapes. | Time-consuming, often requiring more steps. |

| Precision | Highly accurate, maintaining consistent measurements and alignment. | Prone to human error, which can affect design quality. |

| Complexity Handling | Efficiently manages intricate designs without losing detail. | Complex designs may become cumbersome and difficult to execute. |

| Final Output Quality | Produces a clean, unified shape, enhancing overall aesthetics. | Final products can appear less polished and cohesive. |

| Ease of Use | User-friendly interface with minimal learning curve. | Requires advanced skills and experience for effective use. |

“The Weld Tool transforms multiple shapes into a seamless design, enhancing both efficiency and creativity.”

Advanced Techniques with the Weld Tool

The Weld Tool is not only a utility for basic shape combination; it offers advanced techniques that allow proficient users to explore their creativity in design. Understanding and mastering these techniques can significantly enhance your design projects, enabling the creation of intricate and unique shapes. This segment will delve into these advanced methods, focusing on combining multiple shapes and sharing innovative design ideas for unique outcomes.

Combining Multiple Shapes Using the Weld Tool

The ability to combine multiple shapes simultaneously is a powerful feature of the Weld Tool. This technique enhances efficiency and opens up a wider range of design possibilities. To successfully combine shapes, users should follow these key guidelines:

1. Layer Management

Organizing shapes in layers can simplify the welding process. Ensure that overlapping shapes are grouped correctly, allowing for easier selection and manipulation.

2. Alignment and Positioning

Prior to welding, accurately align shapes to achieve seamless combinations. Misalignment can lead to undesired gaps or overlaps that may affect the final outcome.

3. Multiple Selections

Utilize the selection tool to highlight multiple shapes at once. This can be done by holding the shift key while clicking on each shape, allowing for bulk operations without the need to weld one shape at a time.

4. Preview Before Welding

Most design software provides a preview feature that enables you to visualize the outcome of the welding process. This is crucial for identifying any complications before finalizing the weld.

5. Finalizing the Weld

After ensuring everything is in order, apply the weld function to combine the selected shapes into a single entity, allowing for further edits or modifications as needed.

Creative Design Ideas Leveraging the Weld Tool

Harnessing the power of the Weld Tool can lead to innovative design solutions. Here are some creative application ideas that can inspire users to push the boundaries of their design capabilities:

Custom Typography

Users can create unique text designs by welding various shapes into letters. For instance, combining circles and rectangles can produce a bold, eye-catching font style that stands out.

Intricate Patterns

By layering and welding geometric shapes, one can achieve complex patterns that can be used for backgrounds or decorative elements in design projects. This technique is particularly useful in creating mandala designs or ornamental motifs.

Themed Decorations

For seasonal or event-based projects, combining holiday-themed shapes (like stars, pumpkins, or hearts) using the Weld Tool can yield custom decorations that are personalized and creative.

Functional Designs

The Weld Tool can also be applied to functional designs, such as creating custom jigs or stencils. By welding shapes together, users can produce precise, reusable templates for crafts or other applications.

3D Effects

Users can combine shapes to create the illusion of depth and dimension. By strategically overlapping and welding shapes at varying opacities, stunning 3D effects can be achieved in flat designs.By implementing these advanced techniques and creative ideas, users can fully utilize the Weld Tool’s capabilities, resulting in innovative and professional-looking designs that exemplify their artistic vision.

Final Wrap-Up

In summary, the Weld Tool is an indispensable asset for any designer seeking to combine shapes with precision and ease. By applying the techniques discussed, one can avoid common pitfalls and discover the vast potential of their design capabilities. Embracing the Weld Tool not only simplifies the creation process but also opens doors to innovative designs that stand out in any project.