Delving into How to Deboss Paper for an Elegant Effect invites you to explore the captivating art of debossing, a technique that transforms ordinary paper into extraordinary creations. Debossing not only adds texture and dimension but also enhances the aesthetic appeal of various projects, making it a sought-after skill for both amateurs and professionals alike.

This process involves the use of specific materials and tools, allowing for a range of designs that can elevate invitations, stationery, and personal gifts. Understanding the nuances of debossing compared to embossing is essential for achieving the desired results, ensuring that each piece reflects a touch of elegance and sophistication.

Introduction to Debossing

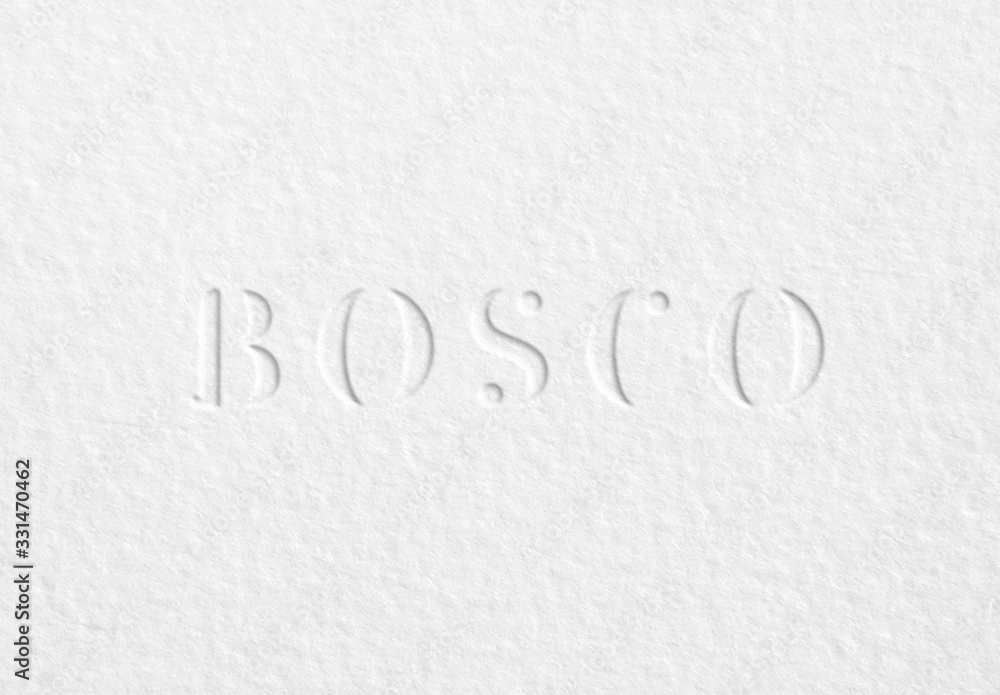

Debossing is a sophisticated printing technique that creates a recessed design on paper or other materials, enhancing the tactile aspect of printed pieces. This method offers a visually striking and elegant effect, making it a popular choice for invitations, business cards, and packaging. The subtle shadows and variations in depth produced through debossing provide an impression of quality and enhance the overall aesthetic appeal.Materials typically used for debossing paper include cardstock, leather, and various types of specialty papers.

These materials are often chosen for their durability and ability to hold fine details without tearing. The debossing process can be achieved using various tools, including debossing plates, heat and pressure machines, or hand tools, depending on the desired outcome and production scale.

Differences Between Debossing and Embossing

While both debossing and embossing involve creating a three-dimensional effect on surfaces, the key difference lies in the direction of the impression. Debossing creates a recessed design that sinks below the surface, while embossing raises the design above the surface, providing a contrasting effect. This distinction affects not only the visual appearance but also the tactile sensations experienced by the touch.The choice between debossing and embossing often depends on the intended message and style of the printed material.

Debossing typically conveys sophistication and elegance, making it suitable for high-end products or formal stationery. On the other hand, embossing can add a playful or dynamic quality to designs, making it well-suited for creative applications, such as greeting cards or promotional materials.

Debossing creates a subtle elegance, while embossing adds a tactile contrast.

In summary, both techniques can be used strategically to enhance the aesthetic value of printed materials, but understanding their differences is essential for selecting the right method for a particular project.

Tools and Equipment for Debossing

Debossing paper is an intricate art that requires specific tools and equipment to achieve the desired elegant effect. Understanding the essential tools and various types of debossing machines will enable artists and crafters to select the right methods for their projects. This section covers the necessary tools, the functions of different machines, and the comparison between manual and automated methods of debossing.

Essential Tools Required for Debossing

A variety of tools are necessary for successful debossing, each serving a unique purpose in the process. The following list highlights key tools indispensable for the debossing technique:

- Debossing Plates: These are metal or acrylic plates engraved with the desired design that will create the debossed effect on the paper.

- Debossing Machine: A mechanism that applies pressure to the debossing plates, transferring the design onto the paper.

- Bone Folder: A tool used to create crisp folds and precise creases, which can assist in placing the paper correctly for debossing.

- Cutting Mat: A protective surface that prevents damage to the workspace and provides grip during the debossing process.

- Brayer: A roller used to apply even pressure when working with debossing plates or to spread ink evenly over a surface.

Types of Debossing Machines and Their Functions

Debossing machines come in various types, each designed to cater to different needs within the debossing process. Understanding their functions can help users choose the most suitable option for their projects. Below are common types of debossing machines:

- Manual Debossing Press: Operated by hand, these presses require physical effort to apply pressure. They offer precise control but may require more time and effort compared to automated options.

- Heat Press: Utilizes heat and pressure to create debossed designs, often suitable for thicker materials. The heat can create a more pronounced effect.

- Digital Die-Cutting Machine: These machines allow for intricate designs to be debossed with minimal effort. Users can program the machine for various designs and settings, offering versatility.

- Embossing Folder Machine: A compact and easy-to-use option that utilizes folders to create both embossing and debossing effects, ideal for home crafters.

Comparison of Manual and Automated Debossing Methods

When it comes to debossing methods, there are distinct advantages and disadvantages to both manual and automated techniques. Understanding these can help crafters choose the best approach for their needs. Here’s a comparative analysis:

“Manual debossing offers greater control and precision, whereas automated methods provide efficiency and speed.”

- Manual Debossing:

- Pros: Greater artistic control, lower initial cost, and no need for electricity.

- Cons: More physically demanding, time-consuming, and less suitable for high-volume projects.

- Automated Debossing:

- Pros: Faster production speed, consistency in results, and the ability to handle complex designs with ease.

- Cons: Higher initial investment and reliance on electricity or batteries.

Preparing the Paper

Selecting the right paper for debossing is crucial to achieving an elegant effect. The type of paper used can greatly influence the quality of the debossing, the visibility of the design, and the overall aesthetic. Factors such as weight, texture, and surface finish all play significant roles in how well the debossing will turn out.To prepare the paper for optimal debossing results, one must consider both its physical attributes and the methods of preparation.

Ensuring that the paper is clean and smooth will allow the debossing tools to work effectively. Furthermore, each type of paper may require specific adjustments or techniques to maximize the debossing effect.

Selection of Appropriate Paper

When choosing paper for debossing, it is essential to consider the following attributes:

- Paper Weight: Heavier paper (typically 80 lb cover or higher) tends to hold the debossed design well, providing deeper impressions without tearing.

- Texture: A smooth texture generally yields better results as it allows for more precise debossing. However, some textured papers can create unique effects that enhance the elegance of the final product.

- Finish: Select papers with a matte or uncoated finish for a refined look; glossy finishes can detract from the clarity of the debossed design.

- Color: Lighter colored papers often provide better contrast and visibility for debossed designs. Dark papers may require deeper impressions to be effective.

Preparing the paper is an essential step that requires careful attention to detail. Ensuring that the paper is flat and free from any wrinkles or creases is vital for achieving a clean debossing result.

Preparation Techniques

The following steps can enhance the preparation of the paper for debossing:

- Flattening the Paper: Place the paper under a heavy book for several hours or use a bone folder to smooth out any imperfections.

- Cutting to Size: Before debossing, cut the paper to the desired dimensions to ensure that it fits correctly within the debossing equipment.

- Test Impressions: Conduct test impressions on scrap pieces to determine the depth and clarity of the debossed design, allowing for adjustments as necessary.

- Humidity Control: Ensure that the paper is stored in a controlled environment to prevent warping or curling, which can impact the debossing process.

Importance of Paper Thickness and Texture

The thickness and texture of the paper are significant factors in achieving an elegant debossing effect. Thicker paper can withstand more pressure, resulting in a deeper and more pronounced debossed design. Conversely, thinner papers may not hold the impression as well and can tear easily during the process.Texture also influences the visual appeal of the debossed designs. Smooth papers typically allow for crisp and clean lines, while textured papers can create a more organic and handcrafted appearance.

“Choosing the right paper not only enhances the debossing quality but also contributes to the overall elegance and sophistication of the final product.”

Debossing Techniques

Debossing is an artful method of creating an impression on paper, giving it a tactile and visual appeal that enhances any project. Understanding the various debossing techniques is essential for achieving the desired elegance in your designs. This section will Artikel fundamental methods for basic debossing as well as more intricate techniques that can elevate your work to an advanced level.

Basic Debossing Techniques

To begin with, mastering basic debossing techniques is crucial for any aspiring artisan. Here is a straightforward step-by-step guide to executing the basic debossing process:

- Choose Your Design: Start with a design that suits your project. Simple shapes, letters, or patterns work best for beginners.

- Prepare the Stamps: Use rubber or metal stamps with the design you wish to deboss. Ensure they are clean and free from any debris.

- Heat the Tool: If using a heated debossing tool, preheat it according to the manufacturer’s instructions. This ensures a clean, crisp impression.

- Position the Paper: Place the paper on a flat, stable surface. Position the stamp or tool directly where you want the deboss to appear.

- Apply Pressure: Firmly press the tool or stamp into the paper. Maintain even pressure for a consistent impression.

- Check the Impression: Carefully remove the tool or stamp to reveal the debossed design. Assess the depth and clarity; repeat if necessary.

Advanced Debossing Methods

For those looking to add a unique touch to their projects, advanced debossing techniques can be employed. These methods allow for more intricate designs and patterns, enhancing the sophistication of your work. A few advanced techniques include:

- Layered Debossing: This method involves debossing multiple layers of paper to create depth. Use various tools or stamps to layer different impressions, resulting in a more dynamic design.

- Foil Debossing: Incorporating foil into debossing can add a luxurious touch. The process involves applying heat-sensitive foil on the debossed area, giving it a shimmering effect.

- Texture Variation: Utilize different materials for your debossing tools, such as textured rubber or wood, to achieve unique surface patterns along with the debossed impression.

- Combination Techniques: Blend debossing with other methods like embossing or printing to create multi-dimensional effects that captivate the eye.

Common Patterns and Designs

There are numerous patterns and designs that lend themselves well to debossing, each providing a distinct character to the final product. The following list includes popular choices among crafters and designers:

- Geometric Shapes: Squares, triangles, and circles offer a modern aesthetic.

- Floral Patterns: Delicate flowers and botanical designs add a touch of elegance.

- Text and Typography: Custom debossed messages or names enhance personal items.

- Abstract Designs: Fluid shapes and lines that create visual movement.

- Nature Themes: Elements such as leaves, trees, or landscapes evoke a serene atmosphere.

Creating Elegant Designs

To achieve an elegant effect through debossing, it is essential to explore a variety of design options suitable for different occasions. This section will focus on crafting refined debossing patterns, combining techniques, and selecting complementary color schemes that enhance the overall aesthetic of the project.

Designing Elegant Debossing Patterns

Creating unique debossing patterns requires an understanding of the event’s theme and the desired impact. Elegant patterns often feature intricate motifs or minimalistic designs that evoke sophistication. Some elegant debossing patterns include:

- Floral motifs suitable for weddings and anniversaries.

- Geometric shapes ideal for modern and corporate settings.

- Classic monograms for personal stationery or invitations.

- Textured backgrounds that add depth without overwhelming the design.

Each of these patterns can be tailored to fit the specific requirements of the occasion, ensuring that the debossing enhances rather than distracts from the overall design.

Combining Debossing with Other Printing Techniques

Integrating debossing with other printing techniques can create a multi-dimensional effect that adds refinement to the finished piece. Techniques such as foil stamping, letterpress, or digital printing can be effectively combined with debossing to achieve a more sophisticated presentation.The benefits of combining these methods include:

- Foil stamping adds a touch of metallic sheen, creating contrast with the debossed elements.

- Letterpress can provide a tactile quality that complements the depth of debossing.

- Digital printing allows for vibrant colors and intricate designs, enhancing the overall appeal.

When executed thoughtfully, these combinations can elevate the design, making it visually striking and elegant.

Color Schemes for Complementing Debossed Designs

Selecting the right color scheme is crucial in ensuring that debossed designs stand out while maintaining an elegant appearance. Color choices should enhance the debossing without overpowering it.Effective color schemes to consider include:

- Monochromatic palettes—using varying shades of a single color creates a cohesive look.

- Pastel combinations—soft hues evoke a gentle, elegant feel, perfect for events like baby showers or spring weddings.

- Bold contrasts—pairing dark debossing on a light background (or vice versa) highlights the texture while maintaining sophistication.

- Earth tones—natural colors provide a rustic elegance suitable for outdoor events or organic-themed designs.

Each of these color schemes can be tailored to the occasion, adding an elegant touch to debossed designs while ensuring that the visual hierarchy is maintained.

“Combining debossing with thoughtful design choices enhances the overall elegance of printed materials, creating truly memorable pieces.”

Tips for Achieving Professional Results

Achieving a professional finish in debossing requires attention to detail and an understanding of the techniques involved. By avoiding common pitfalls, controlling the conditions of your workspace, and maintaining consistency in your work, you can elevate your debossing projects to a level that impresses both you and your audience.

Common Mistakes to Avoid

Several mistakes can undermine the quality of your debossed designs. Recognizing and avoiding these will enhance the effectiveness of your work.

- Inconsistent Pressure: Applying uneven pressure can lead to uneven depth in debossing, resulting in a lack of clarity in the design.

- Insufficient Preparation: Failing to properly prepare your paper, such as not ensuring it is free of moisture, can affect the final outcome.

- Ignoring Temperature: Not considering the temperature settings of your debossing tool can lead to suboptimal results, as some materials respond better to specific heat levels.

Role of Pressure and Temperature

Both pressure and temperature play crucial roles in producing clear and defined debossed designs. The correct application of both can significantly enhance the quality of your results.The pressure applied during debossing affects the depth and clarity of the impression. Too much pressure can tear the paper, while too little may result in a faint or incomplete design. Additionally, temperature is vital; some papers require heating to become more pliable, which improves the debossing process.

Optimal pressure and temperature settings can transform a simple design into a striking feature that captivates the eye.

Maintaining Consistency in Depth and Alignment

Professional-quality debossing hinges on the ability to maintain consistency throughout your work. This involves careful practice and technique.To achieve uniform debossing, consider the following tips:

- Use Guides: Set up guides or templates to ensure consistent placement of your designs across multiple sheets.

- Test Swatches: Always perform test debossing on scrap pieces of the same paper to refine pressure and alignment before working on the final piece.

- Monitor Your Tools: Regularly check and maintain your debossing tools to ensure they operate effectively and uniformly.

By implementing these strategies, you can significantly improve the quality of your debossing projects, achieving results that are both elegant and professional.

Applications of Debossed Paper

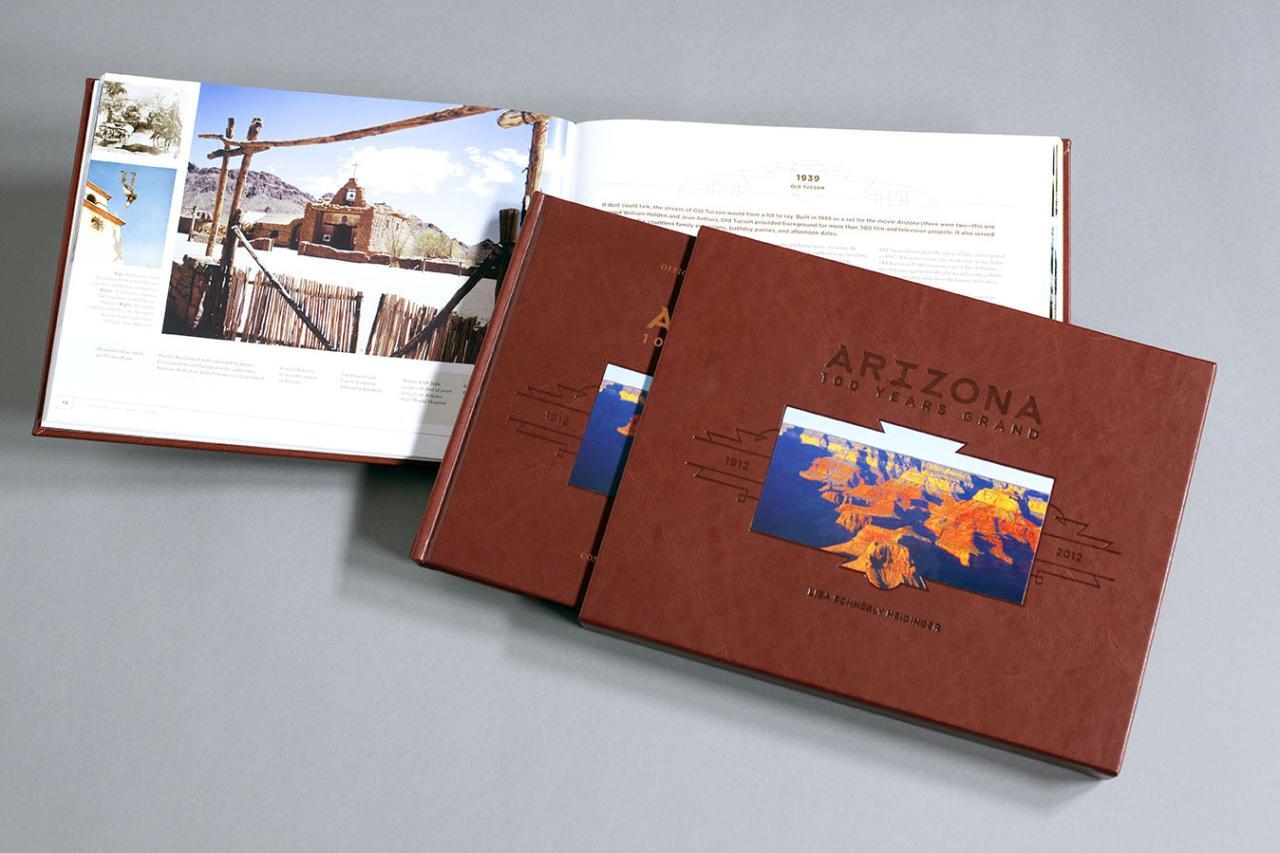

Debossed paper is a versatile medium that finds extensive use across various industries, enhancing the aesthetic appeal and tactile experience of products. This technique allows for intricate designs to be pressed into the surface of the paper, creating a lasting impression that is both elegant and sophisticated. The applications of debossed paper range from personal stationery to high-end commercial products, each serving to elevate branding and presentation.In the realm of packaging and branding, debossed paper adds a layer of sophistication that can significantly influence consumer perception.

Products that benefit from debossed designs include luxury items and artisanal goods, where the tactile quality of the packaging communicates a sense of quality and craftsmanship. Furthermore, in personal projects, debossed paper can transform invitations, greeting cards, and other stationery into memorable keepsakes.

Packaging and Branding

The use of debossed paper in packaging and branding is particularly impactful in industries where presentation plays a crucial role in consumer decision-making. The delicate texture and visual depth of debossed designs create an upscale look and feel, influencing the overall branding strategy. Below are specific examples of products that can benefit from debossed designs:

- Luxury Gift Boxes: Crafted with debossed patterns, these boxes enhance the unboxing experience, making them suitable for high-end retail products like perfumes, jewelry, and gourmet chocolates.

- Business Cards: Debossed business cards convey professionalism and creativity, leaving a memorable impression on potential clients and partners.

- Wine Labels: Debossing on wine labels can highlight vintage details or brand logos, elevating the product’s perceived value and allure.

- Artisan Food Packaging: For gourmet foods and handmade goods, debossed labels and packaging reflect the artisanal nature of the product, appealing to consumers looking for authenticity.

Personal Projects and Stationery

Debossed paper also finds a significant place in personal projects and stationery, adding a touch of elegance and personalization. It enhances the aesthetic quality of invitations and greetings, ensuring that they stand out. The following applications showcase the versatility of debossed paper in personal endeavors:

- Wedding Invitations: Debossed designs can feature intricate patterns or monograms, creating a sophisticated and unique invitation that sets the tone for the event.

- Greeting Cards: Personalized greeting cards with debossed elements add a special touch, making them ideal for birthdays, holidays, and thank-you notes.

- Notebooks and Journals: Custom debossed covers on notebooks enhance their appeal, making them perfect gifts or personal keepsakes.

- Event Programs: Debossing on event programs can highlight important details or the theme of the occasion, making them memorable for attendees.

The tactile and visual impact of debossed paper extends beyond mere aesthetics; it plays a crucial role in the emotional connection that products establish with consumers and recipients alike. By incorporating debossed designs into both commercial and personal projects, creators can craft meaningful experiences that resonate on multiple levels.

Care and Maintenance of Debossed Products

Taking care of debossed paper is essential for preserving its elegant appearance and longevity. Proper maintenance not only enhances the beauty of the embossed design but also ensures the functionality of the paper, especially when used for important projects such as invitations or stationery. By following a few simple care practices, you can maintain the quality of your debossed creations for years to come.

Maintenance Practices for Debossed Paper

To ensure the longevity and pristine condition of debossed paper, it is vital to implement specific maintenance practices. These practices revolve around careful handling, cleaning, and appropriate storage solutions that prevent damage to the debossed designs.

- Avoid Excessive Moisture: Debossed paper is sensitive to moisture, which can lead to warping or damage of the debossed areas. Keep debossed items away from humid environments and avoid exposing them to liquids.

- Limit Direct Sunlight Exposure: Prolonged exposure to sunlight can fade the colors and details of debossed products. Store them in a cool, shaded area to maintain their original appearance.

- Use Acid-Free Materials: When storing or displaying debossed paper, utilize acid-free sleeves or boxes. This helps prevent yellowing and degradation of the paper over time.

- Handle with Care: Always handle debossed products with clean hands to avoid transferring oils or dirt. When necessary, use protective gloves to minimize contact.

Storage Best Practices for Debossed Items

Proper storage is critical for protecting debossed items from damage. Certain conditions must be observed to maintain the integrity of the paper while keeping the designs intact.

- Flat Storage: Store debossed paper flat rather than folded to prevent creases from forming in the debossed areas. Flat storage maintains the delicate texture of the design.

- Archival Boxes: Use archival-quality boxes for storage. These boxes are designed to protect paper from environmental factors that can cause deterioration.

- Temperature Control: Maintain a stable temperature in the storage area. A temperature range of 60°F to 70°F is ideal for preserving paper quality.

- Protective Sleeves: For individual pieces, consider using protective sleeves that are specifically designed to prevent physical damage while allowing visibility.

Cleaning Techniques for Debossed Surfaces

Cleaning debossed surfaces requires careful consideration to avoid damaging the intricate designs. Adopting gentle cleaning methods will help maintain the visual integrity of the debossed features without causing harm.

- Soft Brush Cleaning: Use a soft-bristled brush to gently remove dust or debris from the surface of the debossed paper. This method avoids harsh scrubbing that could damage the design.

- Spot Cleaning: For stains, dampen a soft cloth with water and gently blot the area. Avoid rubbing, as this could fray the paper or distort the debossed impression.

- No Harsh Chemicals: Refrain from using cleaning products that contain bleach or other harsh chemicals. These can discolor the paper and damage the debossed areas.

- Air Dry Only: After any cleaning, let the paper air dry completely in a flat position. Never use heat sources like hair dryers, as they can warp the paper.

Regular maintenance and proper handling of debossed products significantly enhance their durability and aesthetic appeal.

Closing Summary

In conclusion, mastering the art of debossing opens up a world of possibilities for creating stunning and elegant designs that resonate with beauty and style. By employing the right techniques, tools, and materials, you can produce impressive results that enhance your projects and captivate your audience. Whether for personal use or commercial applications, debossed paper stands out as a hallmark of refined craftsmanship.