How to Apply HTV on Wood for Custom Signs is a fascinating journey into the world of crafting unique and personalized decor. This process not only allows for the expression of creativity but also enhances the aesthetic appeal of various spaces. By utilizing Heat Transfer Vinyl (HTV) on wood, crafters can achieve stunning results that serve as memorable gifts or charming additions to homes and events.

Understanding the types of wood that are suitable for HTV application and the advantages it offers, such as durability and versatility, sets the foundation for creating custom signs. As we delve into the intricacies of materials, preparation, and design techniques, you will discover a rewarding craft that opens up a world of customization possibilities.

Introduction to HTV and Wood

Heat Transfer Vinyl (HTV) is a versatile material used in a variety of crafting applications, particularly in creating custom designs on different surfaces. When applied to wood, HTV offers a unique combination of durability and aesthetic appeal, making it an excellent choice for custom signs. This process allows for vibrant designs that can withstand wear and tear, ultimately enhancing the visual impact of wooden projects.

Using HTV on wood surfaces provides several benefits, including an array of color options, ease of application, and the ability to create intricate designs that may be challenging to achieve with traditional painting methods. Furthermore, HTV adheres well to various wood types, ensuring longevity and resistance to peeling or fading. The popularity of custom signs has surged in recent years, finding applications in homes, businesses, events, and outdoor spaces.

These signs not only serve practical purposes, such as providing information or direction, but also contribute to the overall aesthetic of a space.

Types of Wood Suitable for HTV Application

Several types of wood are particularly suitable for HTV application, each offering unique characteristics that can enhance the final product. Understanding these options is crucial for achieving the best results in custom sign creation.

- Pine: This softwood is widely available and easy to work with. It provides a smooth surface that allows for excellent HTV adhesion.

- Birch: Known for its fine grain and light color, birch is an ideal choice for applications where a clean, polished finish is desired.

- Maple: This hardwood offers durability and a beautiful, understated appearance, making it suitable for high-end custom signs.

- Poplar: A budget-friendly option, poplar has a fine texture that works well for HTV, providing a good balance between cost and quality.

- MDF (Medium Density Fiberboard): While technically not solid wood, MDF provides a smooth and consistent surface that is perfect for detailed designs with HTV.

Custom signs made from these wood types find applications in various settings, including residential decor, commercial signage, event branding, and even personalized gifts. Their versatility allows for both indoor and outdoor use, provided proper weatherproofing measures are taken. With the growing trend of personalization, the demand for custom wooden signs continues to rise, reflecting individual tastes and enhancing the charm of any space.

Materials Needed for HTV Application

When embarking on the journey of applying heat transfer vinyl (HTV) to wood, it is essential to gather the right materials to ensure a successful outcome. The selection of quality tools and products will significantly influence the durability and appearance of your custom signs. Below is a comprehensive list of the materials necessary for this creative process.A variety of HTV options exist, and some brands are particularly well-suited for application on wood surfaces.

Choosing the right type of HTV will not only impact the adhesion of the material but will also affect the final aesthetics. Below, you will find a table outlining essential tools for the HTV application process along with their functions.

Essential Materials for HTV Application

To achieve optimal results when working with HTV on wood, it is crucial to utilize quality materials. The following items are integral to the process:

- Heat Transfer Vinyl (HTV): Recommended brands include Siser EasyWeed and Caesar HTV, known for their excellent adherence to wood.

- Wood Surface: Choose a smooth, untreated wood surface to ensure even application.

- Weeding Tool: A weeding tool is used to remove excess vinyl after cutting, ensuring clean designs.

- Heat Press or Iron: A heat press provides consistent heat and pressure, though a household iron can also suffice for smaller projects.

- Protective Sheet: A Teflon or parchment paper sheet protects the HTV during the heat application process.

- Measuring Tools: Rulers or measuring tape help in ensuring accurate placement of the designs on the wood.

- Transfer Tape: This tape allows for easy transfer of the HTV from its carrier sheet to the wood surface.

- Craft Knife: A craft knife is useful for precise cutting and trimming of designs as necessary.

Essential Tools for the HTV Process

The following table summarizes essential tools needed for the HTV application process, along with their respective functions:

| Tool | Function |

|---|---|

| Weeding Tool | To remove excess HTV after cutting, ensuring clean lines and details. |

| Heat Press | Delivers consistent heat and pressure for effective vinyl adhesion. |

| Iron | An alternative to heat press, suitable for small or simpler designs. |

| Protective Sheet | Protects the HTV and wood surface during the heat application. |

| Measuring Tools | Ensures accurate placement of designs on the wood surface. |

| Transfer Tape | Facilitates the transfer of HTV from the carrier sheet to the wood. |

| Craft Knife | Allows for precise trimming and adjustments to the designs. |

“Using high-quality materials and tools is crucial for achieving a professional finish in HTV application on wood.”

Preparing the Wood Surface

To ensure a successful application of heat transfer vinyl (HTV) on wood, it is essential to prepare the wood surface meticulously. Proper preparation not only enhances the appearance of the final product but also significantly improves the adhesion of the HTV, resulting in a long-lasting finish.Sanding and cleaning the wood surface are critical steps in preparing for HTV application. A smooth surface is vital for optimal adhesion because any imperfections can prevent the HTV from sticking properly.

Consequently, it is important to follow a systematic approach to prepare the wood adequately.

Sanding the Wood

Sanding the wood surface creates a smooth and even texture, which is imperative for HTV application. The following steps Artikel the sanding process:

1. Select the Right Sandpaper

Begin with medium-grit sandpaper (around 120-150 grit) to remove any rough spots or imperfections. Follow up with finer-grit sandpaper (220 grit) to achieve a smooth finish.

2. Sanding Technique

Sand in the direction of the wood grain, applying even pressure. This technique minimizes the risk of creating scratches or gouges, ensuring a polished surface.

3. Check for Smoothness

Periodically run your hand over the surface to check for smoothness. Repeat sanding as necessary until the wood feels even and free of any rough areas.

Cleaning the Wood

Once sanding is complete, cleaning the wood surface is the next crucial step. A clean surface is essential to remove any dust or debris that could interfere with adhesion. The cleaning process involves:

1. Dust Removal

Use a soft cloth or a vacuum to remove sanding dust. It is important that no particles remain on the surface, as they can cause bubbles or peeling in the HTV.

2. Wipe with a Damp Cloth

Lightly dampen a cloth with water or a mild cleaning solution to wipe down the wood. This step ensures that any remaining fine dust is removed, providing a pristine surface for HTV application.

3. Drying

Allow the wood to dry completely before proceeding with the HTV application. Moisture can compromise the bond between the HTV and the wood.

Sealing the Wood

In some cases, sealing the wood may be necessary before applying HTV, particularly if the wood is porous or has a rough texture. Sealing helps to create a smooth surface and prevents the adhesive from absorbing into the wood. The sealing process includes:

1. Choosing the Right Sealer

Use a clear wood sealer or a primer specifically designed for use with HTV. Ensure that the product is compatible with vinyl adhesives.

2. Application of the Sealer

Apply the sealer with a clean brush or roller, using thin, even coats. Follow the manufacturer’s instructions regarding drying times and the number of coats required for effective sealing.

3. Final Sanding (Optional)

After sealing, lightly sand the surface again with fine-grit sandpaper to ensure an ultra-smooth finish, followed by another cleaning to remove any dust.By following these steps for preparing the wood surface, you will create an ideal foundation for your HTV application, ultimately leading to a high-quality and durable custom sign.

Designing Your Custom Sign

Creating a custom sign is an exciting process that allows for personal expression and creativity. Leveraging design software is essential in transforming your vision into a tangible product. The right design not only enhances the aesthetic appeal of your sign but also ensures that your message is clearly communicated to your audience.When designing your custom sign, it is important to consider the selection of fonts and images.

The clarity of your message is paramount, and the right choices can significantly impact readability and the overall effectiveness of your sign.

Using Design Software

Utilizing design software can streamline the process of creating your custom sign. Popular options such as Adobe Illustrator, CorelDRAW, or free alternatives like Inkscape allow for intricate designs and easy manipulation of text and imagery. Here are key steps to follow when using design software:

- Begin by setting your canvas size to match the dimensions of your wood surface.

- Choose a suitable color palette that resonates with your intended message and audience.

- Incorporate images and logos, ensuring they are of high resolution to maintain quality during printing.

Choosing Fonts and Images

The selection of fonts and images plays a crucial role in the visibility and overall impact of your sign. Fonts should be easy to read from a distance and aligned with the theme of your design. A combination of bold and script fonts can create an appealing contrast, but it is vital to ensure legibility. Here are some considerations:

- Select fonts that are simple and clean for the main text.

- Avoid using more than two different font styles to maintain consistency.

- Ensure that any images used are relevant, high-quality, and support the message of your sign.

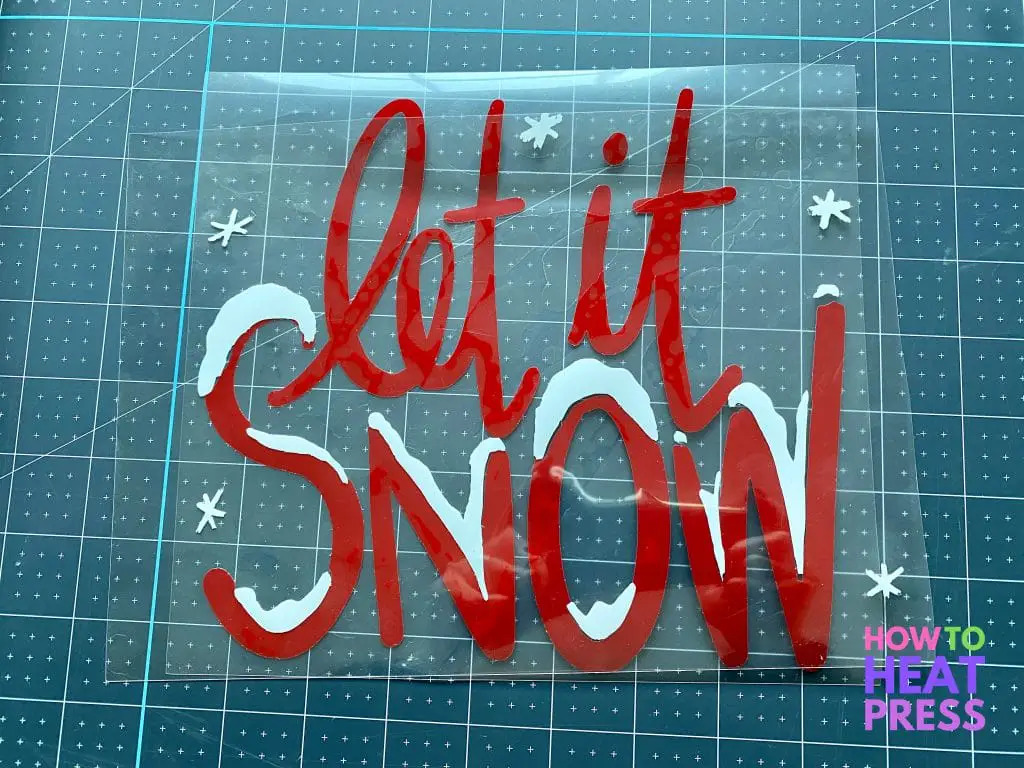

Setting Up the Design for Cutting

Once the design is finalized, setting it up for cutting involves precise layout considerations. Proper alignment and sizing can prevent material wastage and ensure a professional finish. Key steps in this process include:

- Ensure your design is mirrored if you are using HTV, as it will be applied face down on the wood.

- Check the dimensions, ensuring they fit within the cutting machine’s parameters.

- Utilize the software’s preview feature to visualize the final cut before proceeding.

By focusing on these aspects, you can create a striking and effective custom sign that not only meets your aesthetic desires but also communicates your intended message clearly and effectively.

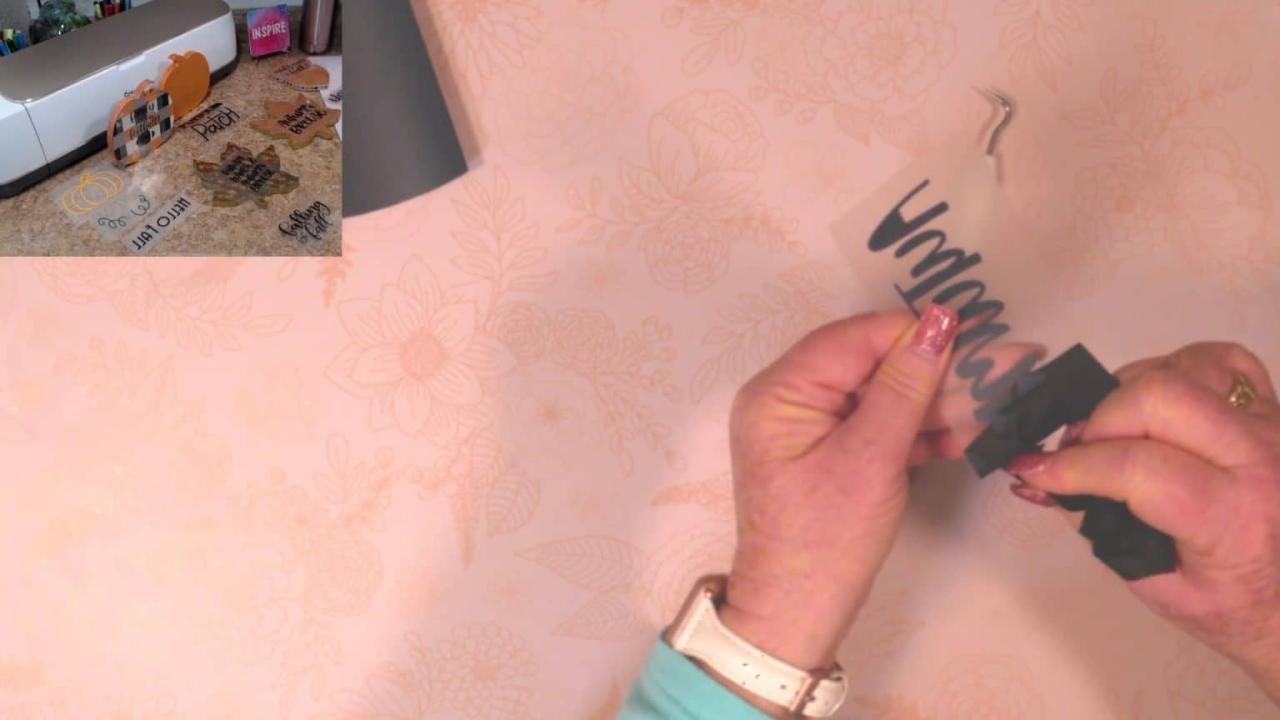

Cutting the HTV

Cutting HTV (Heat Transfer Vinyl) accurately is a crucial step in the process of creating custom signs. This phase determines the precision and quality of the final design. Using a cutting machine not only streamlines the process but also allows for intricate designs that would be challenging to achieve by hand. To begin cutting HTV, it is essential to configure the cutting machine with the appropriate settings.

These settings may vary based on the brand and model of the cutting machine, as well as the thickness and type of HTV used. Below are the recommended steps for cutting HTV effectively.

Machine Settings and Tips

The following are important considerations and settings when preparing to cut HTV:

1. Blade Depth

Adjust the blade depth according to the thickness of the HTV. A standard setting for most HTVs ranges between 1 to 3, but it is advisable to refer to the manufacturer’s guidelines for specifics.

2. Cutting Speed

Set the cutting speed based on the intricacy of the design. Faster speeds can work well for simpler designs, while more complex cuts may require slower speeds to ensure precision.

3. Pressure Settings

Pressure should be adjusted depending on the material. Generally, a medium pressure setting is suitable for HTV. Test cuts can help determine the right pressure for your specific material.

4. Use of a Cutting Mat

Ensure you place the HTV on a suitable cutting mat that is compatible with your machine. This will keep the material stable during the cutting process.Prior to cutting, it is also critical to mirror your designs to ensure they appear correctly when transferred onto the wood surface.

Mirroring Designs

Mirroring your design is an essential step before cutting HTV, particularly for text and intricate shapes. This process ensures that the design will read correctly once applied to the surface. Here’s how to mirror your design effectively:

1. Open Your Design Software

Load your design into the cutting machine’s software.

2. Select the Mirror Option

Most design software will have an option to mirror or flip the design. Enable this setting before proceeding.

3. Preview the Design

Check the preview to confirm that the design appears reversed. This step is vital for text to ensure it reads correctly after application.

4. Finalize the Design

Once confirmed, save the mirrored design and prepare for cutting.

Importance of Test Cuts

Conducting test cuts is a beneficial practice for fine-tuning your machine settings. A test cut will help identify if the blade depth, speed, and pressure are set correctly, which can prevent waste of materials and ensure successful cutting.

1. Select a Small Area

Choose a small design area or a corner of the HTV for the test cut.

2. Perform the Test Cut

Execute the cut using the current settings.

3. Evaluate the Results

Check if the cut has gone through the vinyl without cutting into the backing too deeply. Adjust settings as needed based on the results.

4. Repeat if Necessary

If the test cut is not satisfactory, adjust the blade depth or pressure and repeat until you achieve the desired result.By following these steps and tips, you will be well-prepared to cut HTV accurately, leading to a successful application on wood for your custom sign project.

Applying HTV to Wood

The heat application process is a crucial step in transferring heat transfer vinyl (HTV) onto wood for custom signs. This involves careful attention to temperature, time, and positioning to ensure a successful adhesion. Proper execution will yield a professional-looking finish that enhances the durability and aesthetic appeal of your custom sign.

To initiate the heat application process, it is essential to set your heat press or iron to the appropriate temperature and time for HTV on wood. Generally, the recommended temperature ranges from 305°F to 320°F (about 150°C to 160°C) for most HTV materials. The pressing time typically varies between 10 to 15 seconds, depending on the thickness of the wood and the type of HTV used.

Additionally, using a medium to firm pressure is advisable to ensure the HTV adheres well to the wood.

Positioning the HTV on the Wood Surface

Correct positioning of the HTV on the wood surface is critical for achieving a neat appearance and optimal adhesion. Here are the steps to follow:

1. Preheat the Wood Surface

Before applying HTV, it is beneficial to preheat the wood surface for a few seconds. This will help eliminate any moisture and ensure a better bond between the HTV and wood.

2. Align the HTV Design

Carefully place the HTV on the wood, ensuring that it is aligned as desired. Take your time to check the positioning, as any misalignment can affect the final appearance of your custom sign.

3. Secure the HTV

Use heat-resistant tape to hold the HTV in place if needed. This prevents any shifting during the heat application process.

4. Cover with a Teflon Sheet or Parchment Paper

Always place a protective layer, such as a Teflon sheet or parchment paper, over the HTV before applying heat. This will protect the HTV and the heat press or iron from any potential residue.

During the heat application, there are several key points to monitor to ensure the process goes smoothly:

Monitor Temperature

Ensure that the heat press or iron maintains the set temperature throughout the application process.

Watch the Time

Keep track of the pressing time to avoid overheating the HTV, which can cause it to burn or lose its adhesive properties.

Pressure Application

Apply consistent pressure across the entire surface of the HTV. Uneven pressure can lead to poor adhesion.

Check HTV Adhesion

After the designated pressing time, carefully peel the carrier sheet to check if the HTV has adhered properly. If it lifts, reapply heat.

By following these guidelines, you will achieve a seamless and lasting application of HTV on wood surfaces, resulting in beautiful custom signs that reflect your creativity and design vision.

Post-Application Care

Caring for your custom sign after applying heat transfer vinyl (HTV) is essential to extend its life and maintain its appearance. Proper maintenance ensures that your design remains vibrant and intact, allowing you to enjoy your creation for years to come.To ensure the longevity of your custom sign, it is necessary to establish a routine for cleaning and care. This involves understanding the materials involved and implementing strategies to prevent wear and tear caused by environmental factors.

Cleaning Practices for Custom Signs

Keeping your HTV-covered wooden sign clean is crucial for preserving its aesthetic and condition. The following methods are recommended for effectively cleaning your sign without damaging the HTV:

- Gentle Dusting: Use a soft, dry cloth or feather duster to remove dust and debris regularly. This prevents buildup which can lead to discoloration over time.

- Spot Cleaning: For stains or spills, dab a damp cloth with mild soap on the affected area. Avoid soaking the HTV, as excessive moisture can weaken the adhesive.

- Avoid Harsh Chemicals: Refrain from using abrasive cleaners or solvents that can erode the vinyl surface. Opt for pH-neutral cleaners to maintain the integrity of the HTV.

Preventing Peeling and Damage

Taking proactive measures can significantly reduce the likelihood of peeling or damage occurring on your sign. The following tips are essential for maintaining the integrity of your HTV application:

- Positioning: Hang or display your sign away from direct sunlight and extreme temperatures to prevent fading and heat-related damage. A shaded area is ideal for outdoor displays.

- Humidity Control: High humidity levels can compromise the adhesive bond of the HTV. If possible, maintain a humidity-controlled environment for indoor signs.

- Regular Inspections: Periodically check for any signs of peeling or lifting edges. Addressing these issues early can prevent further damage and prolong the lifespan of your sign.

- Storage: If storing the sign, ensure it is kept in a flat position, ideally covered to protect it from dust and physical damage.

“Regular care and preventive measures are key to maintaining the beauty and functionality of your custom HTV signs.”

Troubleshooting Common Issues

Successful application of heat transfer vinyl (HTV) onto wood can sometimes present challenges. Understanding and addressing these common issues can save time and resources while ensuring a polished final product. This section will identify frequent problems encountered during the HTV application process and provide effective solutions.

Bubbling

Bubbling is a common issue that can occur during the HTV application process, resulting in an uneven surface that detracts from the overall appearance of your custom sign. This often occurs when air is trapped under the vinyl during application or when the temperature is not adequately controlled. To fix bubbling, consider the following steps:

- Use a soft tool, such as a squeegee or credit card, to gently push the bubble towards the edge, releasing trapped air.

- If the bubble persists, use a pin to puncture it and then reapply heat and pressure to ensure adherence.

- Always ensure that your heat press is set to the appropriate temperature and time for the specific type of HTV being used to reduce the likelihood of bubbles forming.

Peeling

Peeling occurs when the HTV does not fully adhere to the wood surface, leading to sections lifting away. This problem can arise from insufficient heat, pressure, or incorrect post-application care. To resolve peeling issues:

- Reapply heat and pressure to the affected areas using a heat press or iron. Ensure the temperature is appropriate for the HTV type.

- Check that you are using the right type of adhesive for your wood surface, as certain HTVs are better suited for different materials.

- Allow the sign to cure fully after application; avoid using water or cleaning products until the HTV has set properly.

Misalignment

Misalignment occurs when the HTV is not placed correctly on the wood, leading to an unprofessional appearance. This can happen during the design or application stages.To fix misalignment issues:

- Carefully peel back the HTV and reposition it, ensuring that it aligns with any registration marks or guidelines.

- If the HTV has already been applied, use a craft knife to trim any excess material to achieve a cleaner edge.

- In future applications, mark the wood surface lightly with a pencil to guide the placement of your design before pressing.

Fixing Mistakes

Mistakes can occur during the application process, but many can be rectified without starting over completely. To effectively address errors:

- If you accidentally cut the HTV incorrectly, use the leftover material to patch the design where necessary.

- For any unwanted adhesive residue, a small amount of adhesive remover or rubbing alcohol can help clean the area without harming the wood.

- Consider the use of additional embellishments or layers to cover minor flaws, enhancing the overall look while correcting the mistake.

Creative Ideas for Custom Signs

Creating custom signs using heat transfer vinyl (HTV) on wood offers a wonderful opportunity to express creativity and personalize spaces. Whether for home decor, gifts, or special events, custom signs can convey meaningful messages or simply add a decorative touch. By utilizing HTV on wood, you can achieve vibrant colors and intricate designs that enhance the aesthetic appeal of any setting.There are numerous themes and occasions where custom signs can serve as unique decorative elements.

From home decor and seasonal celebrations to personalized gifts, the possibilities are nearly endless. Below are some themes and examples that showcase the versatility of custom signs made with HTV.

Popular Themes and Occasions for Custom Signs

Custom signs can be tailored to fit various occasions and themes, making them perfect for diverse settings. Here are some prevalent themes and occasions for which custom signs can be created:

- Weddings: Signs that display the couple’s names, wedding date, or meaningful quotes can serve as beautiful decor during the ceremony and reception.

- Home Decor: Personalize spaces with signs that showcase family names, inspirational quotes, or established dates, perfect for entryways or living rooms.

- Seasonal Celebrations: Create signs for holidays like Christmas or Halloween, featuring festive designs and greetings to welcome guests.

- Baby Showers: Custom signs can announce the baby’s name or share cute messages for the new arrival, adding charm to the celebration.

- Business Branding: Companies can use custom signs to promote their brand names, logos, or services, enhancing visibility and professionalism.

The utilization of HTV on wood allows for various design options, making each sign truly one-of-a-kind. Below are examples of successful custom sign projects that have been well-received.

Examples of Successful Custom Sign Projects

Highlighting successful custom sign projects can inspire creativity and provide practical ideas for your own endeavors. Here are notable examples that showcase the potential of HTV on wood:

- “Welcome Home” Sign: A rustic wooden sign adorned with a family name and a warm greeting can create an inviting atmosphere for guests.

- “Eat” Kitchen Sign: A playful design in vibrant colors can liven up the kitchen space, making it a focal point during meal preparations.

- “Adventure Awaits” Sign: This motivational sign with nature-themed graphics can be a perfect addition to a child’s room or a play area, encouraging exploration and imagination.

- Seasonal Decor Signs: Signs tailored for different seasons, like “Happy Fall” or “Winter Wonderland,” can be switched out throughout the year to keep decor fresh and engaging.

- Personalized Business Signs: Many local businesses have used custom signs to create a distinct brand image, making them instantly recognizable and memorable to customers.

These creative ideas illustrate how HTV can transform simple wooden signs into eye-catching masterpieces that convey personal touch and sentiment. From joyous celebrations to everyday inspiration, custom signs can enhance any environment with their unique charm and style.

Wrap-Up

In conclusion, the art of applying HTV on wood for custom signs is not just a craft but a way to add a personal touch to any environment. By following the Artikeld steps, from preparation to application and care, you can create beautiful signs that stand the test of time. Embrace your creativity and let each project reflect your unique style and ingenuity, making every sign a true representation of your vision.